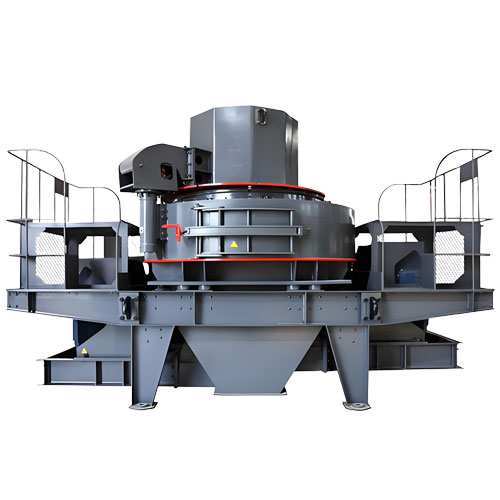

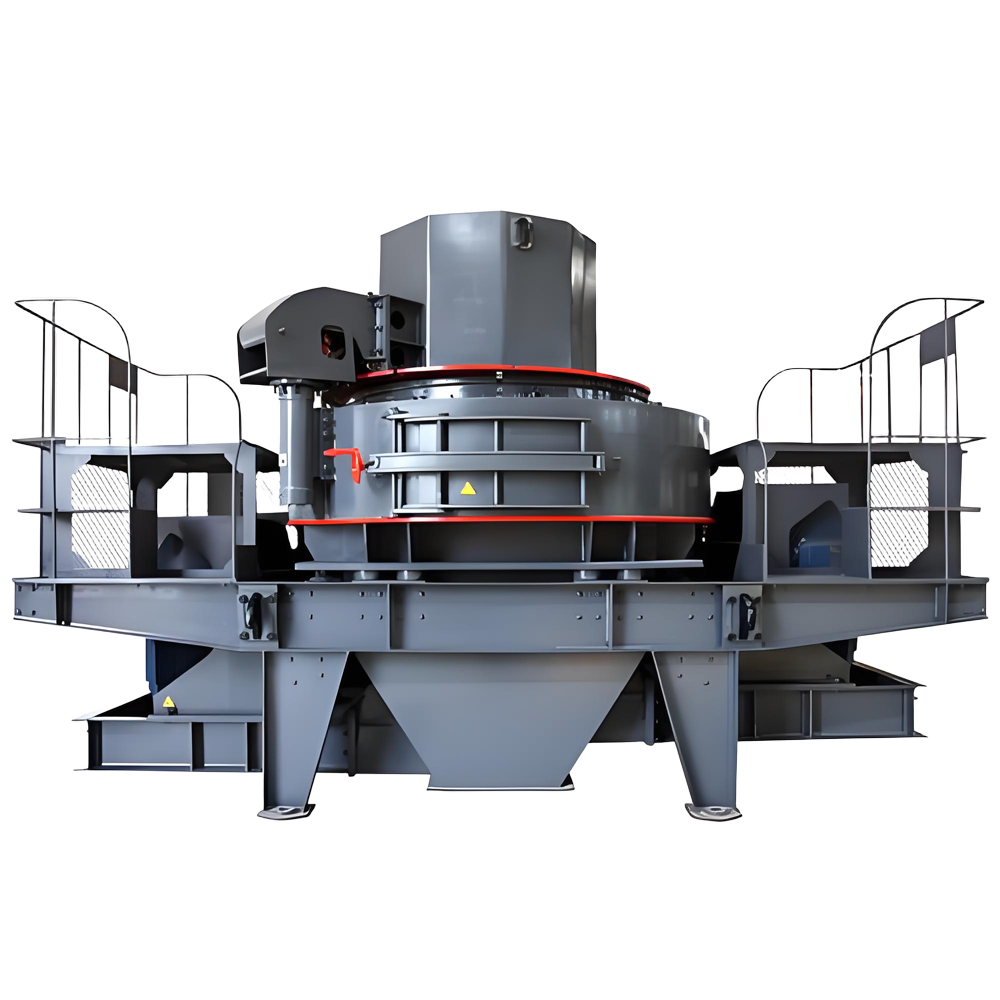

China Sand Making Machine

Tired of inconsistent sand gradation, high wear costs, or low processing efficiency? VSI Crushers – engineered in China to global standards – deliver superior particle shape and maximum operational economy. Produce premium manufactured sand (M-Sand) for concrete, asphalt, and construction at the lowest cost per ton.

Capacity: 200-580 TPH

Max. Feed Size: 65mm

Rotor Diameter: 1150mm

Core Benefits

-

Superior Particle Shape: Produces perfectly cubicle, well-graded aggregates critical for high-strength concrete and premium asphalt applications.

-

Unmatched Production Efficiency: Generates high yields of usable sand & fines, maximizing your return on raw materials.

-

Lower Operating Costs: Advanced wear-resistant materials and optimized rotor designs drastically reduce wear part consumption and downtime.

-

Exceptional Versatility: Efficiently crushes granite, basalt, limestone, river pebbles, quartz, diabase, iron ore, and concrete waste into high-quality sand and aggregates.

-

Intelligent Control: Optional automation systems allow precise control over product gradation and machine operation.

-

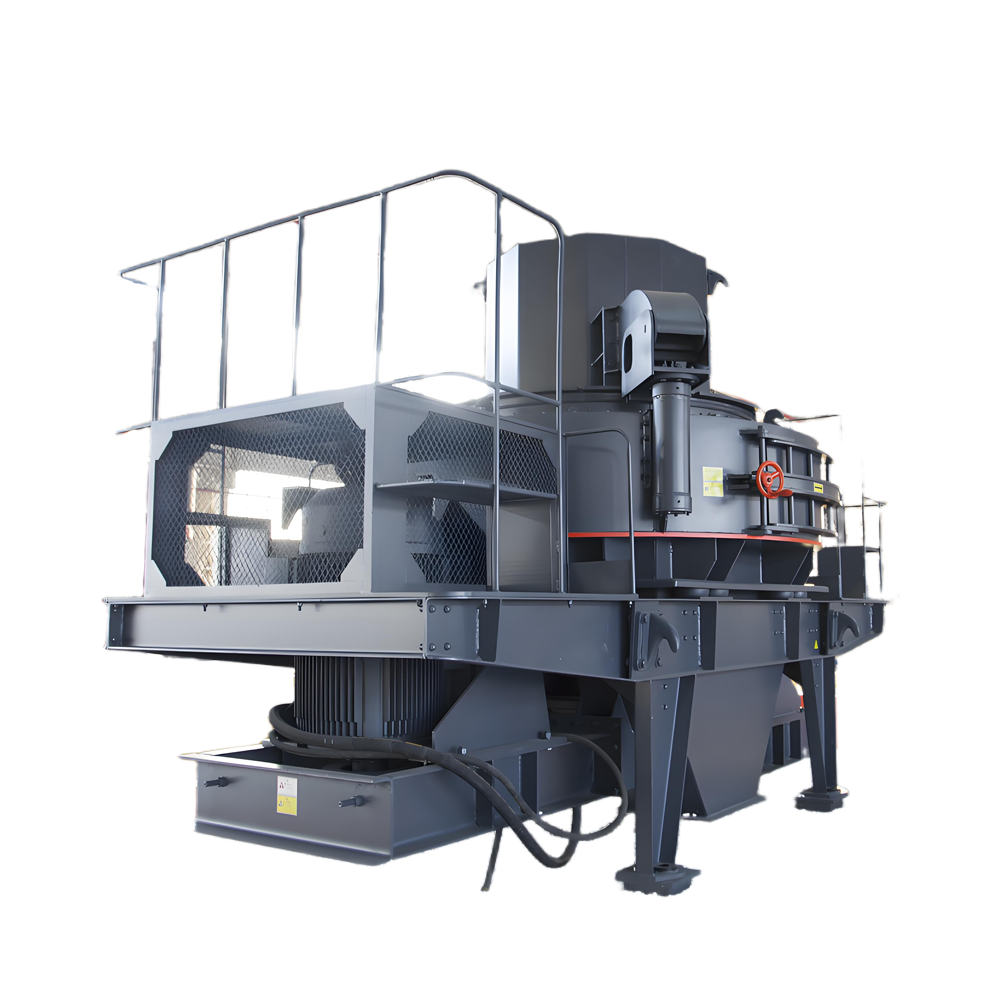

Robust & Reliable: Heavy-duty construction ensures durability and longevity in the toughest operating conditions.

-

Environmental Focus: Designed for reduced dust and noise emissions (add-on systems available).

-

Best-in-Class Value: Combining advanced engineering with China’s manufacturing efficiency for an unbeatable price-to-performance ratio.

Ideal For

-

High-Quality Artificial Sand (Manufactured Sand – M-Sand) Production

-

Shaping Aggregates for Concrete & Asphalt

-

Industrial Minerals Processing

-

Glass Raw Material Production

-

Slag & Concrete Recycling

-

Pre-grinding in Cement Production

-

Mining & Quarrying Operations

Technical Specifications (Model: LH-VSI1145)

| Parameter | Specification |

| Capacity | 200-580 TPH |

| Max. Feed Size | 65mm |

| Rotor Diameter | 1150mm |

| Motor Power | 315-440 kW |

| Finished Sand Size | 0-3mm / 0-5mm |

| Weight | 18.5 Tons |

| Hydraulic System | Lid opening & gap adjustment |

| Warranty | 18 months |

Key Advantages

✅ Perfect Cubic Grain Shape:

Optimized rock-on-rock/rock-on-iron crushing produces isometric aggregates meeting international standards (ASTM C33, BS EN 12620).

✅ 30% Higher Yield:

Deep-cavity rotor design maximizes sand production from raw materials vs. conventional crushers.

✅ 55% Lower Wear Costs:

High-chrome alloy/Ceramic composite wear parts extend service life by 2.5X.

✅ Intelligent Automation:

PLC control system monitors real-time performance and adjusts rotor speed/feed rate automatically.

✅ Eco-Compliant Operation:

Integrated dust suppression and noise-reduction (<75dB) systems.

✅ Global Certifications:

CE, ISO 9001:2015, GOST-R certified.

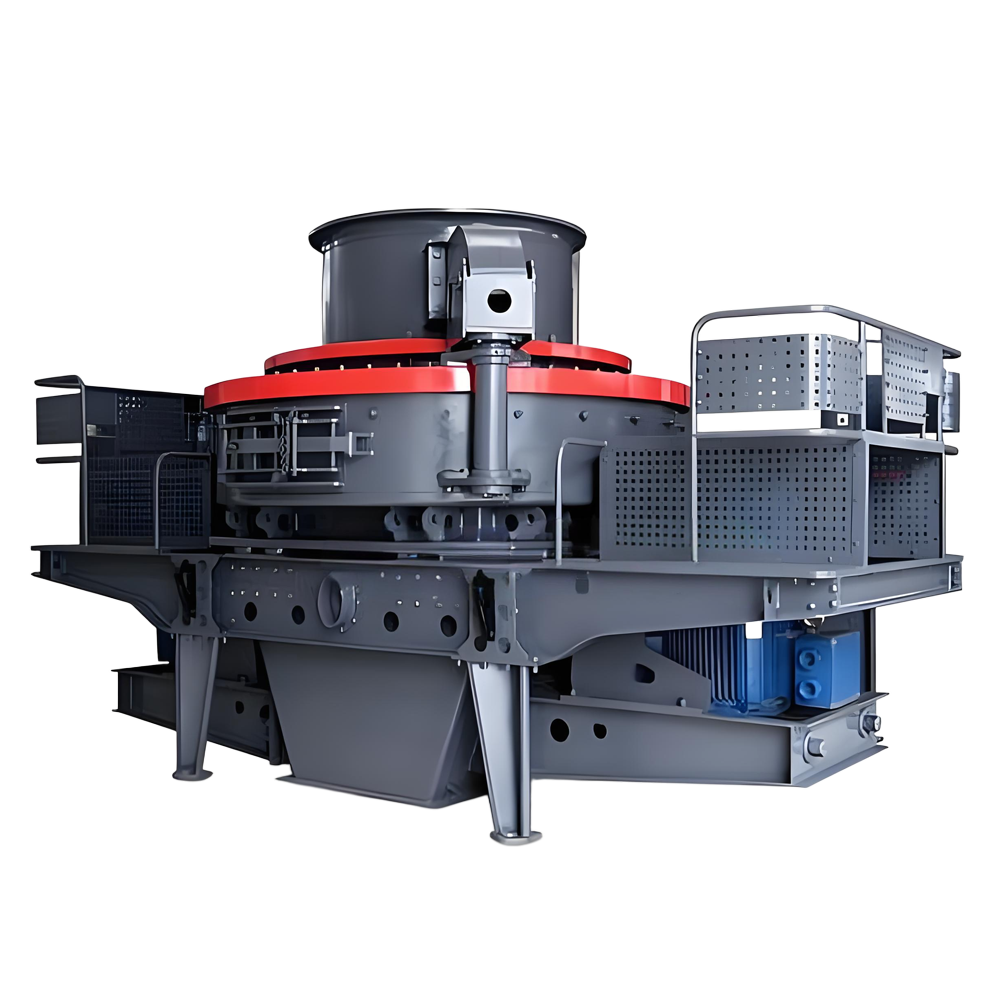

How It Works

- ① Raw material enters crushing chamber

- ② High-speed rotor (1800 rpm) accelerates rocks

- ③ Centrifugal force causes rock-on-rock/rock-on-anvil impact

- ④ Precisely shaped particles pass through adjustable screen

- ⑤ On-spec sand/aggregates discharged via conveyor

Advanced Technology Inside:

-

Optimized Rotor Design: Deep cavity rotor with high tip speed ensures optimal rock-on-rock or rock-on-iron crushing for superior shaping and efficiency.

-

Precision Wear Parts: Interchangeable anvils/liners and distributor caps made from premium wear-resistant alloys maximize service life and simplify maintenance.

-

Hydraulic Adjustment: Easily adjust the gap between the rotor tips and the anvil ring/crushing chamber to control product size without stopping the machine.

-

Robust Bearing System: Heavy-duty roller bearings housed in a rigid base ensure reliable operation under heavy loads.

-

Advanced Lubrication: Automatic centralized grease lubrication system ensures critical components are always protected.

Inquiry

Please leave us your requirements, we will contact you soon.