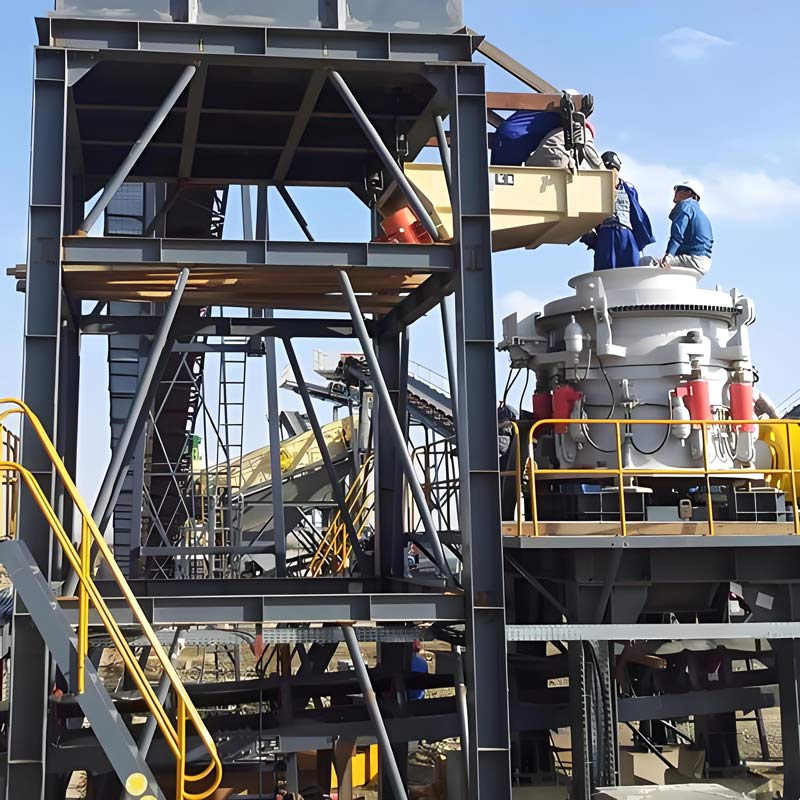

Symons cone crusher

Head Diameter: 600 mm - 2130 mm

Max. Feed Size: 65 - 270 mm

Power Requirement: 75 kW / 100 HP, 300 kW / 400 HP

Approx. Capacity Range: 35 - 1300 MTPH

For nearly a century, the Symons Cone Crusher has set the standard for reliability, productivity, and efficiency in the mining and aggregate industries. As the predecessor to modern cone crusher designs, its robust construction and proven principles continue to make it a highly valued and sought-after solution for demanding reduction crushing applications.

Product Overview

The Symons Cone Crusher is a compression-type machine designed for secondary, tertiary, and quaternary crushing stages. It reduces material by squeezing it between a gyrating mantle and a stationary concave liner (bowl liner). Renowned for its ability to produce a well-graded, cubical product, the Symons cone is the workhorse for hard rock crushing, cement production, and sand and gravel operations.

Key Features & Technological Advantages

1. Robust and Time-Tested Design:

The Symons cone’s heavy-duty, all-steel construction is built to withstand the harshest operating conditions. Its simple yet effective mechanical design ensures long service life and minimal downtime.

2. Symons Principle:

This is the core of its performance. The crusher utilizes a combination of a fixed spindle and an eccentric rotating around it, creating a gyrating and compressive action. This “gyrating” motion, as opposed to a simple pendulum swing, provides a highly efficient and powerful crushing action.

3. Multiple Cavity Configurations:

A key advantage of the Symons cone is its versatility. By using different sets of mantle and bowl liners, the crusher can be configured for various applications:

-

Standard (Coarse) Cavity: Ideal for secondary crushing, producing a coarse product.

-

Short Head (Fine) Cavity: Designed for tertiary and quaternary crushing, producing a finer, more cubical product.

-

Intermediate Cavities: Available to fine-tune the output for specific needs.

4. Hydraulic Adjustment and Clearing:

Modern Symons crushers and retrofitted older models feature hydraulic systems that allow for:

-

Quick Setting Adjustment: Operators can easily adjust the crusher’s closed-side setting (CSS) to control product size, even while the machine is operating.

-

Hydraulic Clearing: In the event of a stall or overload, the hydraulic system can quickly lift the mantle to release tramp metal or uncrushable material, protecting the crusher from damage and allowing for a faster restart.

5. Spring Release System (Traditional Models):

Older, classic Symons cones are famed for their reliable spring release system. If the crusher encounters an overload, the springs compress, allowing the bowl to lift and the uncrushable material to pass, before resetting automatically. This mechanical safeguard is a hallmark of its durability.

6. Consistent Product Quality:

The combination of the gyrating action and the laminar crushing principle (crushing material between layers of particles) ensures a consistent, well-shaped end product with a high percentage of fines in a single pass, reducing the need for re-crushing.

Applications

The Symons Cone Crusher is versatile and suitable for a wide range of materials and industries:

- 1. Mining: Crushing of hard and abrasive ores (copper, gold, iron ore).

- 2. Aggregates: Production of high-quality crushed stone for concrete and asphalt.

- 3. Sand and Gravel: Efficiently producing spec sand.

- 4. Construction & Demolition Recycling: Processing of concrete and asphalt rubble.

- 5. Industrial Minerals: Processing of limestone, granite, basalt, and other quarried rock.

Technical Specifications (Example Range)

Symons Cone Crushers are available in multiple sizes, typically denoted by the diameter of the crushing head (bowl). Common models include:

| Model | Head Diameter | Maximum Feed Size (mm) | Recommended Closed Side Setting (CSS) Range (mm) | Power (kW / HP) | Approximate Capacity* (MTPH) |

|---|---|---|---|---|---|

| 2FT / 600mm | 600 mm (24″) | 65 – 85 | 8 – 25 | 75 kW / 100 HP | 35 – 120 |

| 3FT / 900mm | 900 mm (36″) | 85 – 115 | 9 – 38 | 110 kW / 150 HP | 60 – 245 |

| 4¼ FT / 1295mm | 1295 mm (51″) | 145 – 175 | 13 – 38 | 150 kW / 200 HP | 115 – 400 |

| 5½ FT / 1650mm | 1650 mm (66″) | 190 – 220 | 13 – 51 | 220 kW / 300 HP | 245 – 700 |

| 7FT / 2130mm | 2130 mm (84″) | 230 – 270 | 16 – 51 | 300 kW / 400 HP | 455 – 1300 |

Why Choose a Symons Cone Crusher?

-

1. Proven Reliability: With a history spanning generations, its design is trusted worldwide.

-

2. Low Operating Costs: Durable components and simple maintenance lead to a lower cost-per-ton over the crusher’s lifetime.

-

3. Excellent Product Shape: Known for producing a high-value, cubical product that meets strict specifications.

-

4. Wide Availability of Parts: A global supply network ensures that spare parts and liners are readily available.

-

5. Adaptability: The ability to change crushing cavities makes it a flexible solution for changing production needs.

Conclusion

The Symons Cone Crusher is more than just a piece of machinery; it is an industry icon. Its legacy of robust performance, operational efficiency, and consistent output makes it a smart and economical choice for any operation focused on high-volume, precision reduction crushing. Whether you are sourcing a new unit from a manufacturer that continues the tradition or investing in a well-maintained used model, the Symons cone delivers proven value that stands the test of time.

Contact us today to find the right Symons Cone Crusher configuration for your specific application and production goals.

Inquiry

Please leave us your requirements, we will contact you soon.