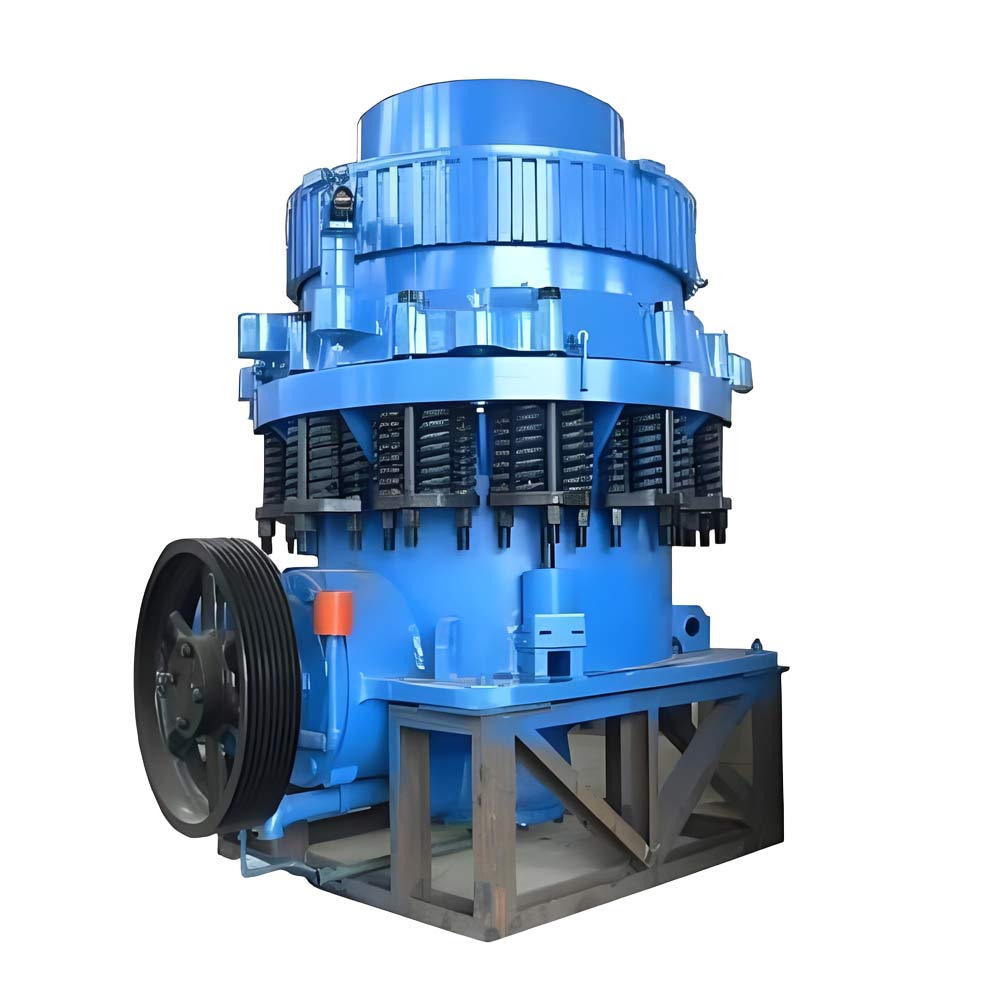

Spring cone crusher

Cone Diameter: 600 mm (24"), 900 mm (36"), 1200 mm (48"), 1750 mm (69"), 2200 mm (87")

Feed Opening: 50 - 350 mm (2" - 14") depending on the model and chamber type.

Max. Feed Size: 40 - 300 mm (1.5" - 12")

Processing Capacity: 15 - 1100 t/h (Highly dependent on material, CSS, and chamber type)

In the fields of mining, metallurgy, construction, and building materials, the demand for high-quality, efficient crushing equipment is ever-growing. The Spring Cone Crusher stands out as a core piece of machinery designed to handle medium to hard materials, delivering reliable performance, superior particle shape, and long-term operational stability. As a classic and widely trusted crushing solution, it has become an indispensable asset for enterprises aiming to optimize production efficiency and reduce operational costs.

Core Working Principle: Precision Crushing Driven by Mechanical Excellence

The Spring Cone Crusher operates on the principle of compression crushing, leveraging the coordinated movement of a rotating mantle (inner cone) and a fixed concave (outer cone) to apply high-pressure forces to materials. Here’s a detailed breakdown of its working process:

- 1. Material Feeding: Raw materials (such as granite, basalt, iron ore, limestone, and quartzite) are evenly fed into the crushing cavity through the feed hopper.

- 2. Crushing Process: The motor drives the eccentric shaft to rotate via a V-belt and pulley. This rotation causes the mantle to swing in a circular motion—when it approaches the concave, materials are squeezed, crushed, and ground; when it moves away, the crushed materials fall under gravity to the next section of the cavity for further refinement.

- 3. Discharge Control: The final crushed products are discharged through the bottom of the cavity, with the particle size adjustable by adjusting the gap between the mantle and concave.

A key design highlight is the spring safety system, which acts as a protective barrier against overloads. If uncrushable objects (e.g., metal debris) enter the cavity, the springs compress to expand the discharge gap temporarily, allowing the foreign objects to pass through. Once cleared, the springs reset automatically, ensuring the crusher resumes normal operation without manual intervention—greatly reducing downtime and equipment damage risks.

Outstanding Technical Advantages: Why Choose Spring Cone Crusher?

Compared to other crushing equipment (such as jaw crushers or impact crushers), the Spring Cone Crusher offers unique benefits tailored to medium-hard material processing:

① High Crushing Efficiency & Low Energy Consumption

- The optimized “deep cavity” design of the crushing chamber allows for a larger feeding capacity and longer material residence time, ensuring full crushing in a single pass. This reduces the number of reprocessing cycles, 提升 (increasing) production efficiency by 15-20% compared to traditional cone crushers.

- Advanced hydraulic adjustment technology (available in premium models) enables quick and precise control of the discharge gap, eliminating the need for time-consuming manual adjustments. This not only saves labor costs but also ensures consistent product particle size—critical for industries requiring strict quality standards (e.g., concrete aggregate production).

② Superior Product Quality & Uniform Particle Shape

- The crushing process relies on compression rather than impact, minimizing excessive fragmentation and producing cubical-shaped particles with low needle-like or flaky content. This high-quality output is ideal for applications like road construction, high-strength concrete, and asphalt mixing, where particle shape directly affects structural performance.

- The wear-resistant components (mantle and concave) are made of high-chromium alloy steel, which offers excellent hardness and toughness. This extends their service life by 30-50% compared to ordinary steel parts, reducing the frequency of replacements and lowering maintenance costs.

③ Robust Structure & Reliable Operation

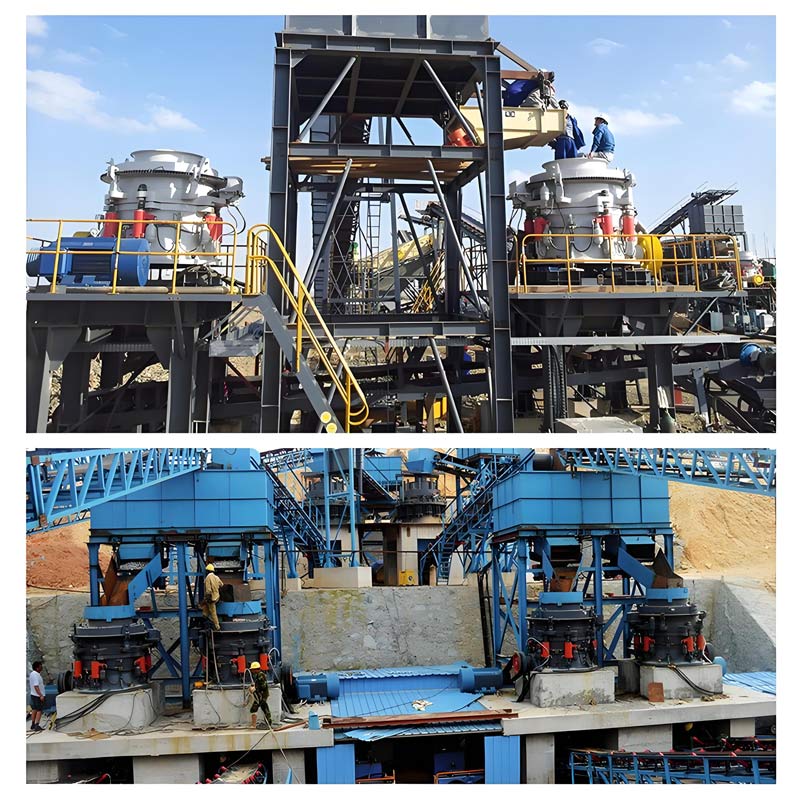

- The heavy-duty frame is fabricated from high-quality cast steel, with a reinforced design at stress points to withstand high impact and pressure. This ensures stable operation even in harsh working environments (e.g., underground mines, open-pit quarries with large temperature variations).

- The sealed lubrication system (adopting grease or oil lubrication) prevents dust, water, and impurities from entering the internal components, reducing wear on bearings and gears. This design significantly improves the crusher’s operational reliability and extends its overall service life to 8-10 years (with proper maintenance).

④ Wide Application Range

The Spring Cone Crusher is highly versatile and can process a wide range of materials with compressive strength up to 350 MPa. Its typical applications include:

- Mining: Crushing iron ore, copper ore, gold ore, and other metal ores into coarse or fine aggregates for beneficiation.

- Construction: Producing high-quality aggregate for concrete, cement, and road base materials.

- Building Materials: Crushing limestone, gypsum, and dolomite for cement, lime, and wallboard production.

- Infrastructure: Processing granite and basalt for highway, railway, and bridge construction.

Model Selection & Customization Options

To meet the diverse needs of different industries and production scales, we offer a full range of Spring Cone Crusher models, with capacities ranging from 50 t/h to 1,500 t/h and discharge particle sizes from 5 mm to 100 mm. Key models include:

- Standard Model: Suitable for coarse crushing (discharge size 40-100 mm) in large-scale mines and quarries.

- Medium-Fine Model: Designed for medium and fine crushing (discharge size 15-40 mm) in aggregate production lines.

- Super-Fine Model: Ideal for ultra-fine crushing (discharge size 5-15 mm) in industries like glass manufacturing and precision casting.

In addition, we provide customization services to adapt the crusher to specific working conditions:

- Optional dust suppression systems for environmentally sensitive areas.

- Explosion-proof designs for processing flammable materials (e.g., coal).

- Mobile crushing stations (integrating the Spring Cone Crusher with a chassis) for on-site construction projects, eliminating the need for material transportation and reducing logistics costs.

After-Sales Support & Maintenance Tips

To ensure our customers maximize the value of their Spring Cone Crusher, we offer comprehensive after-sales services:

- Installation & Commissioning: Our professional team provides on-site guidance for equipment installation, alignment, and test runs to ensure smooth startup.

- Spare Parts Supply: We maintain a global inventory of genuine spare parts (mantles, concaves, bearings, etc.) and offer fast delivery to minimize downtime.

- Technical Training: We conduct training sessions for operators and maintenance personnel, covering equipment operation, daily inspection, and troubleshooting.

For daily maintenance, we recommend:

- Checking the lubrication system regularly to ensure sufficient oil/grease and clean filters.

- Inspecting the wear of mantle and concave weekly and replacing them when the wear reaches the limit.

- Clearing the feed hopper and crushing cavity of debris before starting the equipment to avoid overloads.

Conclusion

The Spring Cone Crusher is a high-performance, cost-effective crushing solution that combines advanced technology, robust design, and versatile application. Whether you are operating a large mine, a construction aggregate plant, or a building materials factory, it can help you achieve higher production efficiency, better product quality, and lower operational costs.

Contact us today to learn more about our Spring Cone Crusher models and customized solutions—let us partner with you to drive your production success!

Inquiry

Please leave us your requirements, we will contact you soon.