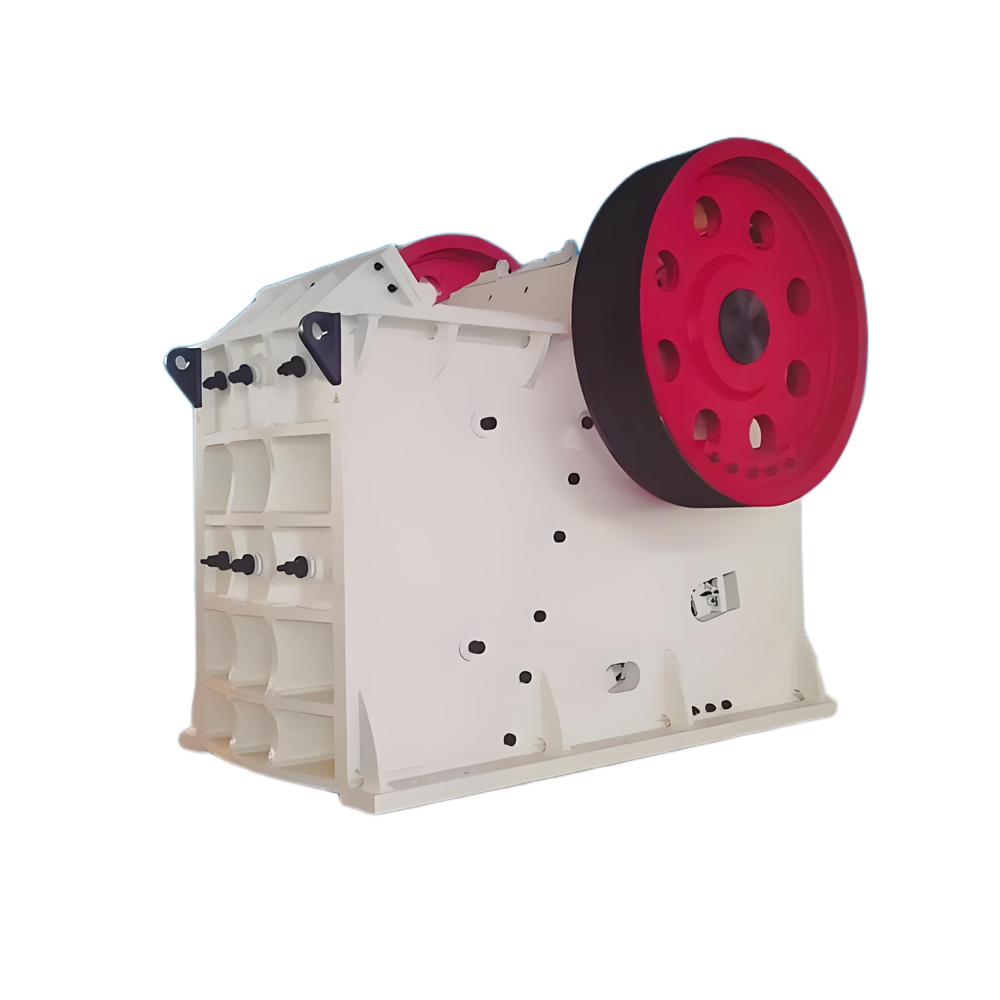

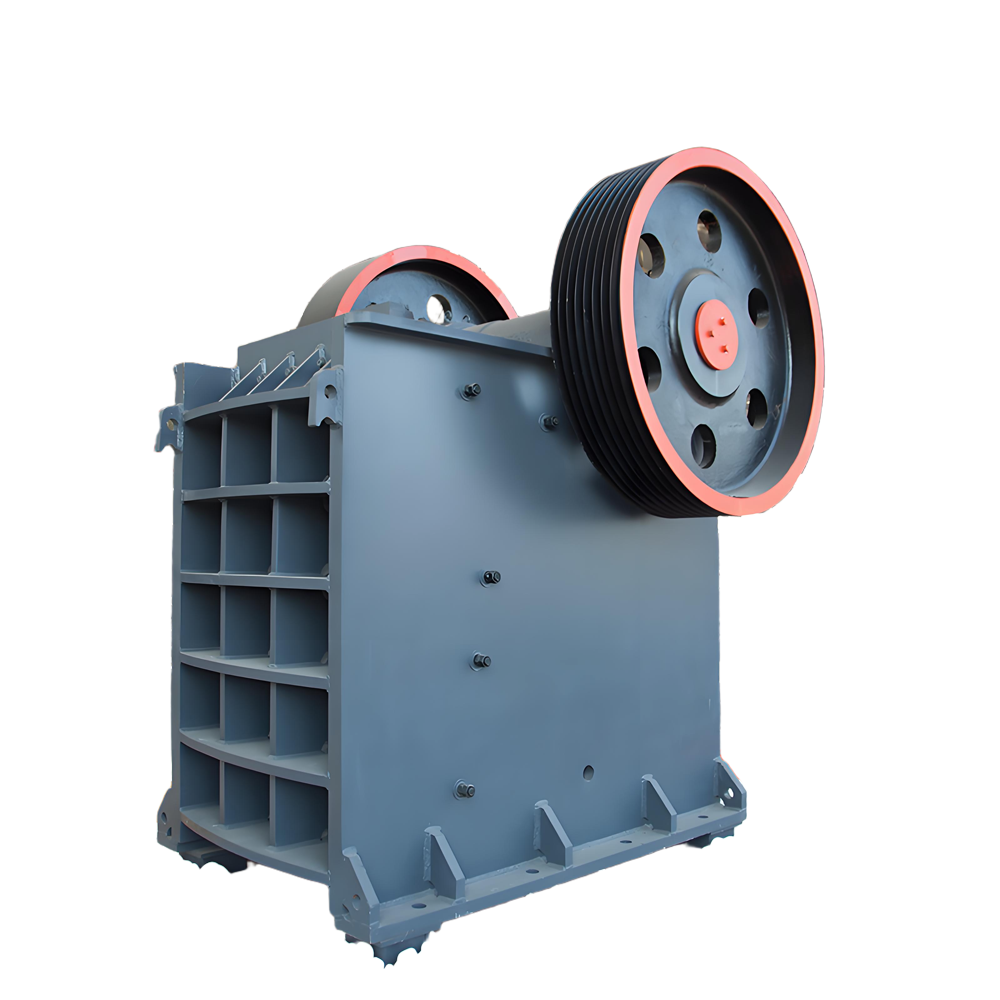

Small Limestone Crusher

Feed Opening: 250 x 400 mm

Max. Feed Size: ~ 210 mm

Capacity: 15 - 50 Tons/Hour

Discharge Adjustment: 20 - 80 mm

Product Introduction

Our Small Limestone Crusher is a robust, efficient, and highly versatile machine designed specifically for processing medium-hardness materials like limestone, brick, concrete, and other aggregates. Engineered for small to medium-scale operations, quarries, construction sites, and recycling projects, this crusher delivers powerful performance in a compact and user-friendly package. It is the ideal solution for primary or secondary crushing where space and budget are key considerations, transforming large, unusable rocks into valuable, uniformly sized gravel, sand, or dust.

Whether you are a contractor looking to recycle demolition waste or a quarry owner supplying local construction, this crusher maximizes your productivity and return on investment.

Key Features & Advantages

-

1. Compact Design & High Mobility: Its small footprint allows for easy placement on confined job sites. Many models are mounted on a wheeled trailer, making transportation between sites quick and effortless.

-

2. Powerful Crushing Performance: Don’t let its size fool you. Equipped with a strong jaw or impact mechanism and a reliable motor, it efficiently reduces limestone chunks to desired sizes with high throughput.

-

3. Robust & Durable Construction: Built with high-quality steel and wear-resistant components, the crusher is designed to withstand the abrasive nature of limestone, ensuring a long operational lifespan and reduced maintenance costs.

-

4. Simple Operation & Easy Maintenance: The user-friendly design requires minimal training to operate. Key components are easily accessible for routine maintenance, cleaning, and part replacement, minimizing downtime.

-

5. Versatile Application: Capable of handling not only limestone but also concrete, bricks, pavers, and other construction debris, making it a perfect tool for recycling projects.

-

6. Cost-Effective Solution: Low initial investment, minimal operational costs, and high efficiency make this crusher an exceptionally profitable asset for small businesses.

Technical Parameters Table

Note: Parameters can vary by model. The following table provides a typical specification range.

| Parameter | Specification | Details |

| Feed Opening | 250 x 400 mm | (Approx. 10″ x 16″) |

| Max. Feed Size | ~ 210 mm | (Approx. 8 inches) |

| Capacity | 15 – 50 Tons/Hour | Varies based on material and output size. |

| Power Source | Electric Diesel | 22-37 kW (30-50 HP) / Diesel Engine option |

| Weight | 4,000 – 7,000 kg | (Approx. 8,800 – 15,400 lbs) |

| Overall Dimensions (LxWxH) | ~ 2,000 x 1,800 x 1,600 mm | Compact for easy transport. |

| Discharge Adjustment | 20 – 80 mm | Adjustable to produce different aggregate sizes. |

Industries & Applications

This small limestone crusher is an invaluable asset across multiple sectors:

-

1. Construction & Demolition: On-site crushing of concrete rubble and demolition waste to create reusable base material for new construction, reducing disposal costs and material transportation.

-

2. Small Quarries & Mines: Primary crushing of blasted limestone to produce aggregate for road base, railroad ballast, and construction aggregate.

-

3. Agriculture: Crushing limestone into agricultural lime (aglime) to neutralize soil acidity and improve crop yields.

-

4. Landscaping & Paving: Producing decorative gravel, stone dust for pathways, and base materials for patios and driveways.

-

5. Recycling Centers: Processing masonry, concrete, and other inert materials for reuse in new projects, supporting environmental sustainability.

FAQ: Small Limestone Crusher

Q1: What is the final product size I can achieve?

A1: The final product size is adjustable. By changing the gap between the crusher’s jaws or adjusting the impact aprons, you can produce anything from coarse gravel (e.g., 40-50mm) down to fine dust (0-5mm). A vibrating screen can be added to the process for precise product classification.

Q2: Can this crusher handle materials other than limestone?

A2: Absolutely. While optimized for medium-hardness materials like limestone, it is also highly effective for crushing concrete, bricks, asphalt, and other construction aggregates. It is not recommended for extremely hard rocks like granite or quartzite without specific wear-resistant liners.

Q3: What are the power source options?

A3: To ensure maximum flexibility, our crushers are available with either an electric motor (ideal for fixed locations with power access) or a diesel engine (perfect for remote sites or mobile operations).

Q4: How difficult is the maintenance?

A4: Maintenance is straightforward. Regular tasks include lubricating bearings, checking wear parts like jaw plates or blow bars, and ensuring all bolts are tight. The design prioritizes easy access to these components to keep maintenance simple and downtime to a minimum.

Q5: Do you provide support for installation and operation?

A5: Yes. We provide detailed installation manuals, operation guides, and instructional videos. Furthermore, our technical support team is available to assist you remotely or, if necessary, arrange on-site service.

Q6: Are spare parts readily available?

A6: Yes. We maintain a comprehensive inventory of common wear parts like jaw plates, liners, and bearings. This ensures fast delivery and minimal disruption to your operations when parts need replacement.

Inquiry

Please leave us your requirements, we will contact you soon.