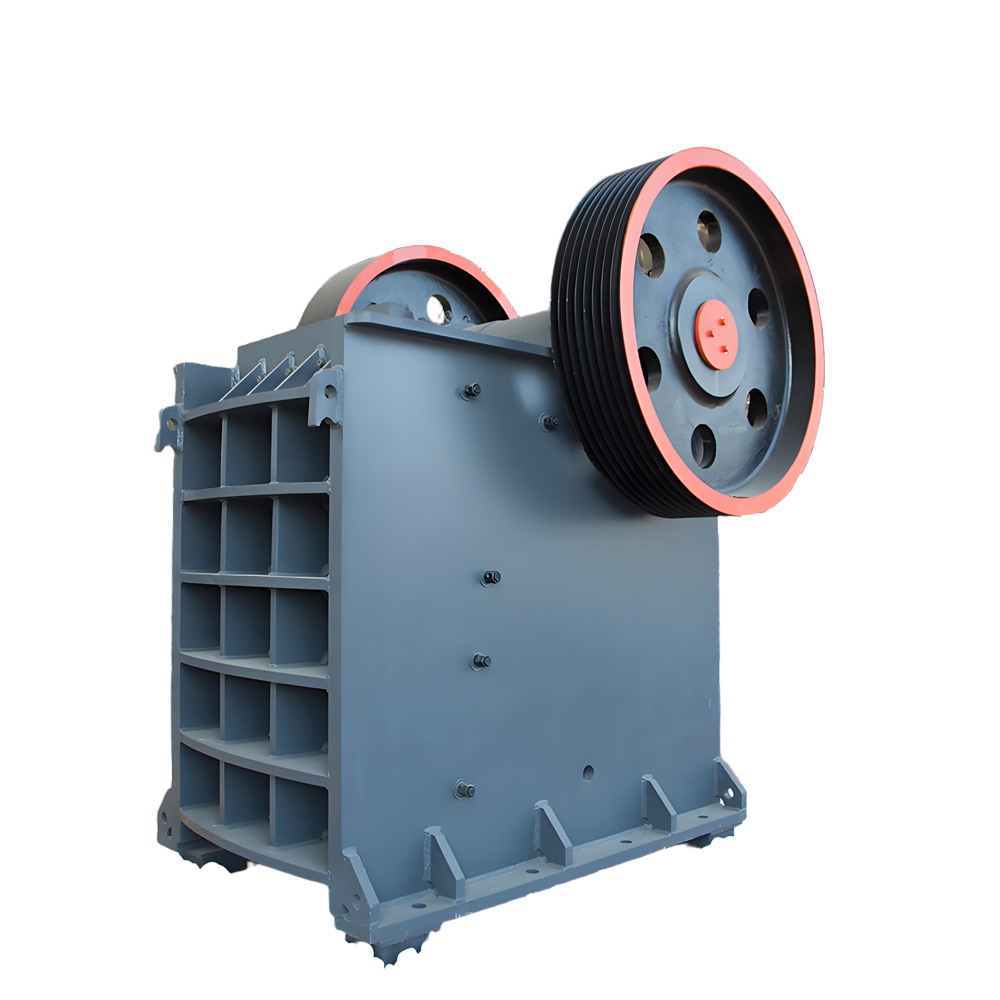

Jaw Rock Crusher

The Jaw Rock Crusher is an essential piece of equipment for industries requiring efficient and reliable rock crushing. Its robust design, high performance, and adaptability make it a top choice for primary crushing operations. Feed Opening (mm): 580×960, 850×1200, 1200×1800 Max Feed Size (mm): 1000 Capacity (t/h): 50 to 600 t/h

Jaw rock crusher overview

The Jaw Rock Crusher (also known as a jaw crusher) is a robust and highly efficient primary crushing machine designed to break down hard and abrasive rocks, ores, and minerals. It is widely used in mining, quarrying, construction, and recycling industries due to its simple structure, reliable operation, and high crushing ratio.

Jaw rock crusher key features

High Crushing Efficiency – Powerful jaw movement ensures effective reduction of large-sized rocks into smaller, manageable particles.

Durable Construction – Made from high-quality materials (e.g., manganese steel) to withstand heavy-duty applications.

Adjustable Discharge Size – The gap between the jaws can be adjusted to control the output size, making it versatile for different applications.

Low Maintenance – Simple design with fewer moving parts reduces downtime and maintenance costs.

Versatile Applications – Suitable for crushing granite, basalt, limestone, concrete, and other hard materials.

Jaw rock crusher working principle

The rock crusher operates on the principle of compressive force. The movable jaw plate exerts pressure on the fixed jaw plate, breaking the rocks into smaller fragments. The crushed material is discharged through the bottom opening, which can be adjusted to achieve the desired particle size.

Technical Specifications

| Model | Feed Opening (mm) | Max Feed Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kW) |

| Model 96 | 580×960 | 500 | 50-200 | 50-180 | 55-75 |

| Model 120 | 850×1200 | 750 | 80-250 | 150-350 | 90-132 |

| Model 180 | 1200×1800 | 1000 | 100-300 | 300-600 | 160-250 |

Jaw rock crusher applications

-

Mining & Quarrying – Primary crushing of gold, copper, iron ore, and other minerals.

-

Construction & Demolition – Crushing concrete, bricks, and asphalt for recycling.

-

Aggregate Production – Producing gravel and sand for road construction and concrete plants.

-

Laboratory Use – Small-scale jaw crushers for sample preparation in labs.

Inquiry

Please leave us your requirements, we will contact you soon.