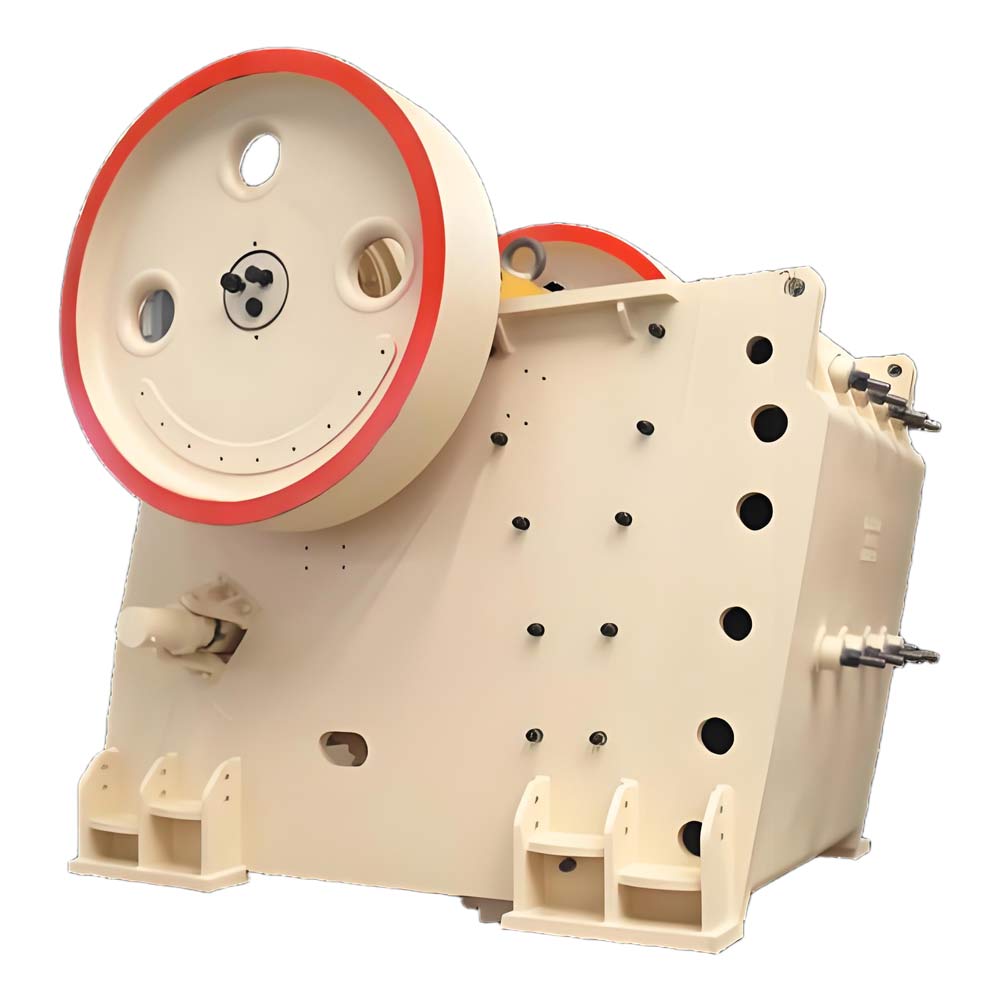

For relentless primary crushing in the most demanding mining environments, our Heavy-Duty Jaw Crusher is engineered to be the cornerstone of your mineral processing circuit. Built for endurance, efficiency, and maximum productivity, it is designed to process massive quantities of hard, abrasive ores like granite, basalt, and iron ore with unparalleled reliability.

Uncompromising Performance and Efficiency

At the heart of every mining operation is the need to reduce large, run-of-mine material to a manageable size for downstream processing. Our jaw crusher excels in this primary role, delivering:

-

1. High Crushing Capacity: Process more material in less time, increasing the overall throughput of your plant.

-

2. Superior Reduction Ratio: Efficiently reduce large feed material (up to 1,500mm) to a uniform product size, often in a single pass.

-

3. Robust Throughput: Designed to handle high tonnages, ensuring a consistent and reliable feed to your SAG or ball mills.

Key Features & Engineering Excellence

1. Rugged Frame and Durable Components

-

Heavy-Duty Structure: The crusher frame is constructed from high-grade, annealed steel plate, providing exceptional strength and resistance to shock loads.

-

Premium Jaw Dies: Manganese steel crushing jaws are designed for optimal nip-angle and crushing motion. They are reversible and replaceable, maximizing service life and reducing downtime.

2. Advanced Crushing Chamber Design

-

Optimized Geometry: The chamber is designed to accelerate material into the crushing zone, promoting inter-particle crushing and enhancing efficiency while minimizing wear.

-

Deep Symmetrical V-Crushing Chamber: Ensures less tramp metal headaches and allows for higher capacity and a superior end-product shape.

3. Reliability and Easy Maintenance

-

Spherical Roller Bearings: Large, self-aligning bearings withstand high shock loads and are located in dust-tight, split housings for easy access and maintenance.

-

Hydraulic Adjustment: The closed-side setting (CSS) can be adjusted quickly and safely using hydraulic tools, allowing for precise control over product size without the need for manual shims.

-

Toggle and Seat System: A robust toggle plate acts as a safety device, protecting the crusher from uncrushable material by fracturing under extreme pressure.

4. Safety First

-

Integrated Guards: All moving parts are fully guarded to ensure operator safety.

-

Maintenance-Friendly Design: Easy access to the crushing chamber and lubrication points simplifies routine inspections and liner changes.

Technical Specifications (Example Model: JC-1500)

| Parameter | Specification |

|---|---|

| Feed Opening | 1,500mm x 1,200mm (59″ x 47″) |

| Max. Feed Size | 1,250mm (49″) |

| Capacity | Up to 1,500 mtph (depending on material and CSS) |

| Power | 300 kW (400 HP) |

| Closed Side Setting (CSS) Range | 150 – 300mm (6″ – 12″) |

| Total Weight | ~ 85,000 kg (187,000 lbs) |

Note: Specifications vary by model. Contact us for a detailed datasheet.

Applications in Mining

Our jaw crushers are the primary choice for a wide range of hard rock mining applications, including:

-

1. Primary Crushing of Run-of-Mine (ROM) Ores: Gold, Copper, Iron Ore, Nickel, Zinc.

-

2. Aggregate Production from Quarried Rock.

-

3. Pre-crushing for Semi-Autogenous Grinding (SAG) Mills.

-

4. Processing of Industrial Minerals.

Why Choose Our Jaw Crusher?

-

1. Proven Track Record: Trusted by major mining companies worldwide.

-

2. Reduced Cost-Per-Tonne: High efficiency and low wear parts cost translate to a lower total cost of ownership.

-

3. Global Support & Service: 24/7 technical support, a global parts distribution network, and expert service teams to keep your operation running.

-

4. Customizable Solutions: We offer a range of models and configurations to perfectly match your specific mine plan and feed material.

Ready to Optimize Your Primary Crushing Stage?

Contact our team of mining experts today to discuss your project requirements and discover how our Heavy-Duty Jaw Crusher can drive productivity and profitability in your operation.

Inquiry

Please leave us your requirements, we will contact you soon.