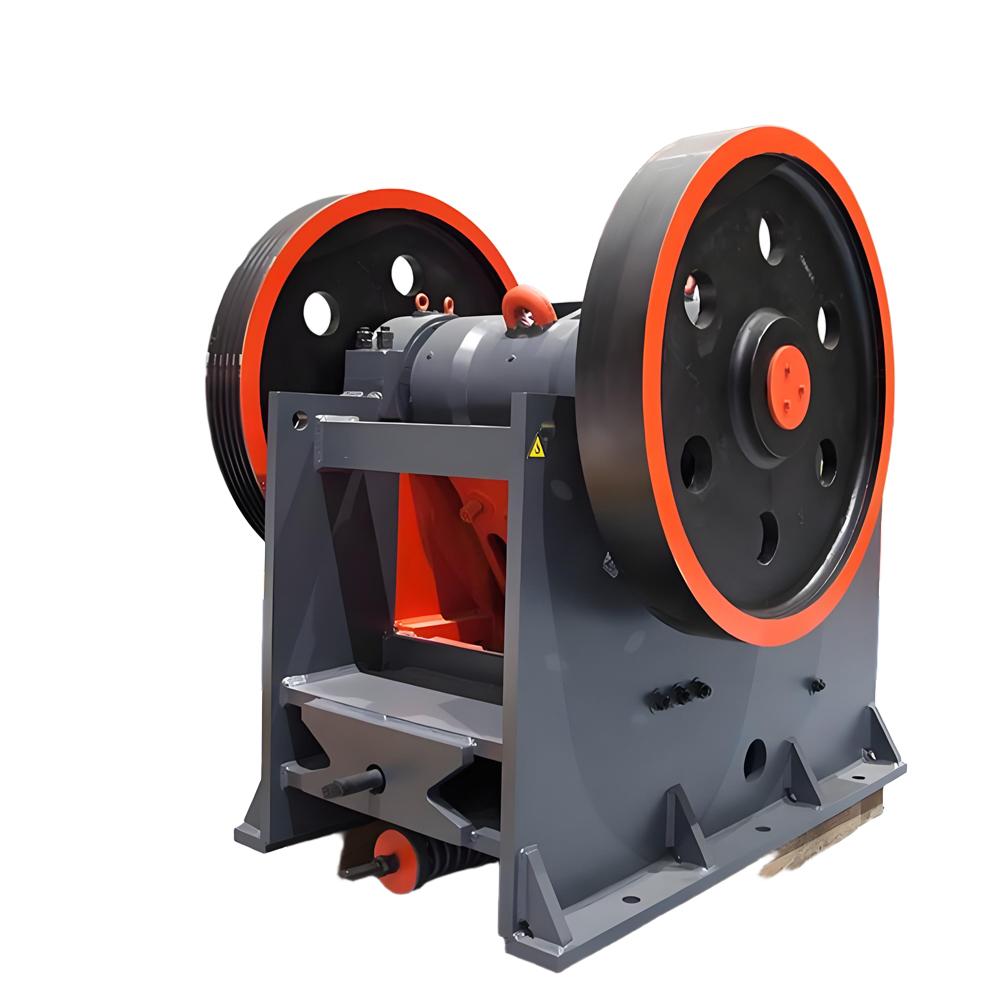

Concrete Jaw Crusher

Feed Opening: 30" x 42" (750 x 1060 mm)

Max. Feed Size: 26" (650 mm)

Closed Side Setting (CSS) Range: 4" - 8" (100 - 200 mm)

Capacity (Depending on CSS & Material): 150 - 350 TPH

Product Introduction

Our Concrete Jaw Crusher is a robust, high-performance crushing machine engineered specifically for the primary reduction of hard, abrasive materials like concrete, demolition waste, reinforced concrete, and asphalt. It is the workhorse of recycling, mining, and construction sites, designed to transform large, irregular chunks of concrete into uniformly sized, manageable aggregate for reuse in new projects. Built with a focus on durability, efficiency, and ease of maintenance, this crusher delivers unparalleled reliability, ensuring maximum uptime and a rapid return on investment.

Key Features & Advantages

-

1. Exceptional Durability & Robust Construction

-

Heavy-Duty Frame: Fabricated from high-grade, welded steel plate, the crusher body is built to withstand the extreme forces and shock loads of crushing concrete with rebar.

-

High-Quality Jaw Dies: The crushing jaws are made from premium manganese steel, offering exceptional wear resistance and a long operational life, even in the most abrasive conditions.

-

-

2. Superior Crushing Performance

-

Aggressive Crushing Action: The deep crushing chamber and optimized toggle angle create an aggressive “nip” that ensures efficient size reduction and high production capacity.

-

Variable Speed Control: Many models feature adjustable jaw speeds, allowing operators to fine-tune the output product size and shape for specific application requirements.

-

-

3. Enhanced Safety & Ease of Maintenance

-

Integrated Safety Guards: Full protection for flywheels, drives, and other moving parts ensures operator safety.

-

Hydraulic Adjustment: The closed-side setting (CSS) can be adjusted quickly and safely using a hydraulic system, minimizing downtime and manual labor.

-

Easy Access Design: Key components are easily accessible for routine maintenance, liner changes, and cleaning.

-

-

4. Mobility & Versatility

-

Stationary and Mobile Configurations: Available as stationary plants for fixed operations or as part of mobile tracked crushers for on-site mobility, providing flexibility for any project scale.

-

Handles Contaminated Material: Effectively crushes concrete with embedded rebar, wire mesh, and other light contaminants. An integrated over-band magnet can often be added to automatically remove ferrous material.

-

Technical Parameters Table

The following table provides sample specifications for a mid-range model. Specifications will vary by model.

| Parameter | Specification |

| Feed Opening | 30″ x 42″ (750 x 1060 mm) |

| Max. Feed Size | 26″ (650 mm) |

| Closed Side Setting (CSS) Range | 4″ – 8″ (100 – 200 mm) |

| Capacity (Depending on CSS & Material) | 150 – 350 TPH |

| Drive Power | 150 HP (110 kW) |

| Total Weight (Crusher Only) | ~55,000 lbs (25,000 kg) |

| Key Feature | Hydraulic CSS Adjustment & Overload Protection |

Industries & Applications

Our Concrete Jaw Crushers are indispensable in a wide range of industries:

-

1. Construction & Demolition (C&D) Recycling: Primary crusher for processing demolished concrete structures, slabs, and sidewalks into valuable recycled concrete aggregate (RCA).

-

2. Quarrying & Mining: Primary crushing of blasted limestone, granite, and other abrasive rock.

-

3. Infrastructure Development: Crushing concrete from road, bridge, and airport runway repairs and upgrades.

-

4. Site Clearance & Land Development: On-site processing of concrete foundations and waste to reduce hauling costs and provide base material for new construction.

-

5. Asphalt Recycling: Primary reduction of old asphalt millings for reuse in new hot mix or cold mix asphalt.

FAQ: Concrete Jaw Crusher

Q1: Can this jaw crusher handle concrete with steel rebar?

A: Yes, absolutely. Our crushers are specifically designed to process reinforced concrete. The powerful crushing action breaks the concrete and exposes the rebar, which is then typically removed by an optional over-band magnet during the process.

Q2: What is the final product size I can achieve?

A: The final product size is determined by the Closed Side Setting (CSS) – the narrowest gap between the jaw plates. A smaller CSS produces a finer product, while a larger CSS produces a coarser product. Our hydraulic adjustment system allows for quick and easy changes to the CSS.

Q3: What kind of maintenance is required?

A: Regular maintenance includes periodic greasing of bearings, checking jaw die wear, and monitoring hydraulic systems. The design prioritizes easy access to these components to minimize maintenance time and costs.

Q4: Is the crusher available as a mobile unit?

A: Yes. This jaw crusher can be the core of a stationary plant, but it is also commonly mounted on a tracked mobile chassis. This creates a self-contained, mobile crushing plant that can be easily moved around a site or between projects.

Q5: How does the crusher protect itself from uncrushable objects?

A: Our crushers are equipped with an overload protection system, often a toggle plate designed to break under extreme stress or a hydraulic release system that automatically opens the jaws to release tramp iron or other uncrushable material, preventing serious damage to the crusher.

Q6: What are the benefits of using recycled concrete from your crusher?

A: Using recycled concrete aggregate (RCA) significantly reduces project costs by eliminating landfill fees and the need to purchase new virgin aggregate. It is also an environmentally sustainable practice that conserves natural resources and reduces the carbon footprint of your project.

Inquiry

Please leave us your requirements, we will contact you soon.