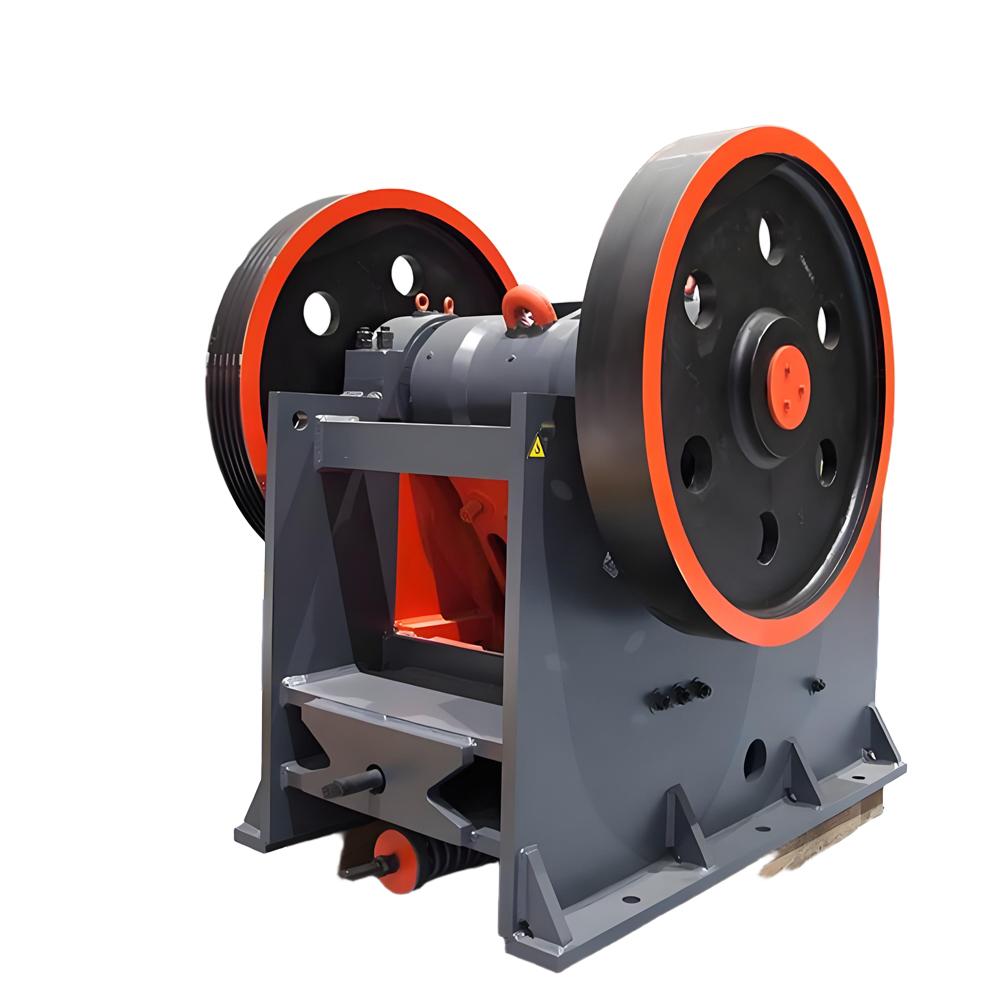

200 TPH Rock Jaw Crusher

Feed Opening: 1200 mm x 1500 mm (47" x 59")

Max. Feed Size: 1000 mm (39")

Capacity: Up to 200 - 750 TPH (Depending on material and CSS)

Closed Side Setting (CSS) Range: 150 - 300 mm (6" - 12")

Product Overview

Our 200 TPH Rock Jaw Crusher is a heavy-duty, high-performance machine engineered for primary crushing of hard and abrasive materials like granite, basalt, and river gravel. Designed for stationary and portable plant configurations, this crusher delivers a consistent output of up to 200 tons per hour, making it the ideal solution for medium to large-scale quarrying, mining, and aggregate production operations. Built with durability and efficiency at its core, it ensures maximum productivity and a lower cost per ton.

Key Features & Benefits

-

1. Robust Construction & Heavy-Duty Frame

-

The crusher features a stress-relieved, welded steel frame that can withstand the high forces of primary crushing. This ensures long-term reliability and stability under the most demanding conditions.

-

-

2. High Crushing Efficiency & Deep Crushing Chamber

-

The optimized cavity design and deep crushing chamber allow for a large feed opening and high reduction ratio, enabling the crusher to process large-sized rocks efficiently and achieve excellent particle shape.

-

-

3. Reliable Eccentric Shaft & Heavy-Duty Bearings

-

A forged, high-quality eccentric shaft is supported by heavy-duty, spherical roller bearings. This provides high load capacity and reliable performance, ensuring smooth operation and extended service life.

-

-

4. Advanced Safety & Adjustment System

-

The crusher is equipped with a hydraulic adjustment system to easily change the closed-side setting (CSS) for quick product size changes. The hydraulic toggle release system automatically clears the crushing chamber in the event of a stall, protecting the crusher from severe damage and reducing downtime.

-

-

5. Durable Jaw Plates

-

Manufactured from high-grade manganese steel, the reversible jaw plates offer a long service life. Multiple tooth profiles are available to match your specific application and material characteristics.

-

-

6. User-Friendly Operation & Low Maintenance

-

Designed for easy maintenance, with accessible lubrication points and replaceable wear parts. This design philosophy minimizes routine service time and operational costs.

-

Technical Parameters Table

| Parameter | Specification |

|---|---|

| Model | JC-1500 / PE-1200×1500 (Typical) |

| Feed Opening | 1200 mm x 1500 mm (47″ x 59″) |

| Max. Feed Size | 1000 mm (39″) |

| Capacity | Up to 200 – 750 TPH (Depending on material and CSS) |

| Closed Side Setting (CSS) Range | 150 – 300 mm (6″ – 12″) |

| Eccentric Shaft Speed | ~220 rpm |

| Power Requirement | 160-200 kW (200-250 HP) |

| Weight (Crusher Only) | Approx. 50,000 kg (110,000 lbs) |

| Main Frame | Fabricated steel plate, stress-relieved |

Note: Specifications are indicative and may vary depending on the specific model and material properties (e.g., hardness, density, moisture content).

Application Scenarios

The 200 TPH Jaw Crusher is versatile and widely used in:

-

1. Mining and Quarrying: Primary crushing of gold, copper, and iron ore; crushing of granite, limestone, and other aggregates.

-

2. Aggregate Production: Serving as the primary crusher in stationary crushing plants for producing base course, concrete, and asphalt aggregates.

-

3. Construction & Demolition Recycling: Processing C&D waste like concrete and rubble for reuse as a recycled aggregate.

-

4. Infrastructure Projects: Used in large road and railway construction projects to produce on-site materials.

Case Study Example: Granite Quarry in Texas

A major aggregate producer in Texas integrated our 200 TPH Jaw Crusher as the primary unit in their new 500 TPH plant. The crusher consistently processes 24-inch granite boulders, producing a 6-inch minus product for secondary crushing. The result was a 15% increase in overall plant throughput and a 30% reduction in unplanned downtime due to the crusher’s reliability and easy maintenance features.

Frequently Asked Questions (FAQ)

Q1: What is the meaning of “200 TPH”?

A: TPH stands for “Tons Per Hour.” It indicates the crusher’s designed capacity to process up to 200 tons of material in one hour under specific conditions (e.g., feed size, material hardness, and desired product size).

Q2: What is the recommended power source for this crusher?

A: The crusher requires an electric motor in the range of 160-200 kW (200-250 HP). The drive system typically uses V-belts for efficient power transmission and overload protection.

Q3: How often do the jaw plates need to be replaced?

A: The lifespan of jaw plates depends heavily on the material being crushed and the production volume. For highly abrasive rock, plates may last several months, while for less abrasive materials, they can last over a year. Regular inspection is key.

Q4: Can this crusher handle recycled concrete with rebar?

A: Yes. The hydraulic toggle release system is designed to protect the crusher from uncrushable material like tramp iron. While rebar will not typically damage the crusher, it is recommended to use an overhead magnet to remove rebar before crushing to improve efficiency and product quality.

Q5: Do you provide installation and commissioning services?

A: We offer comprehensive technical support, including detailed installation drawings, foundation plans, and on-site commissioning services conducted by our expert engineers to ensure optimal performance from day one.

Inquiry

Please leave us your requirements, we will contact you soon.