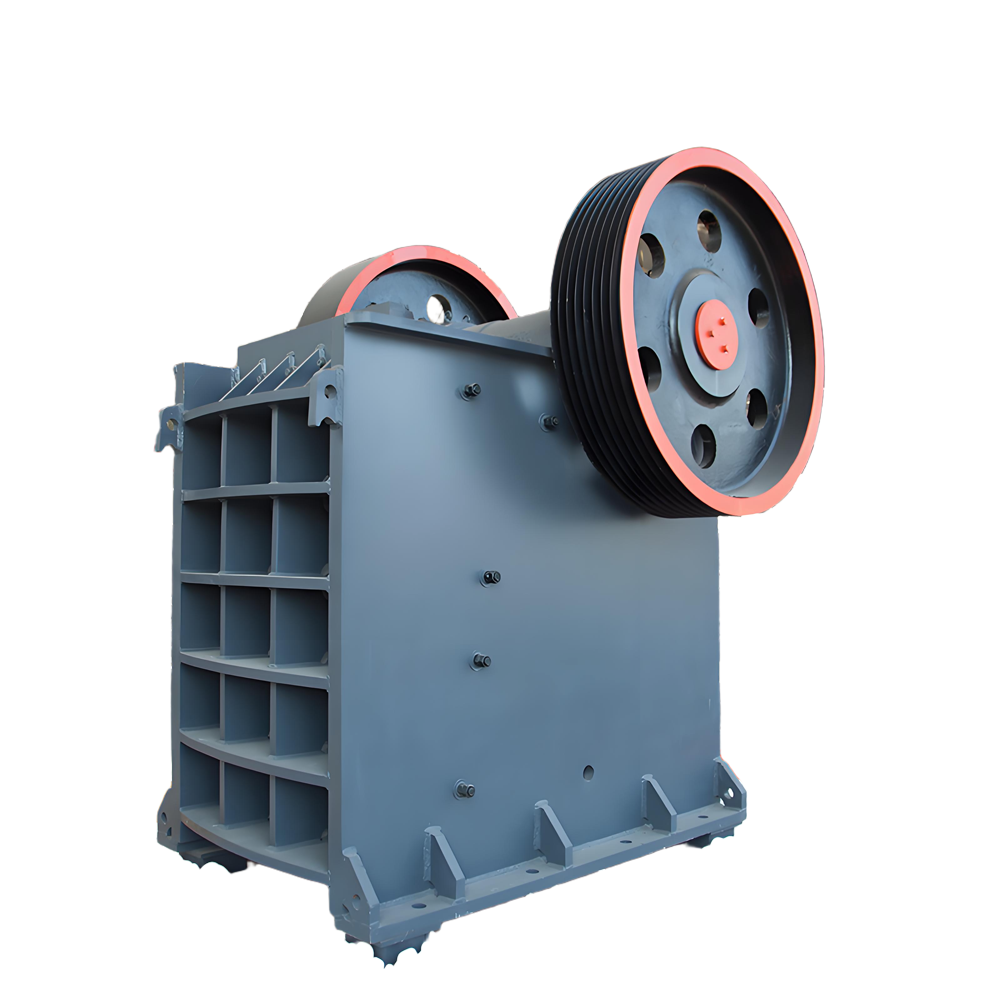

150 TPH Rock Jaw Crusher

Feed Opening: 750mm x 1060mm (30" x 42")

Max. Feed Size: 630mm (25")

Closed Side Setting (CSS) Range: 75mm - 200mm (3" - 8")

Capacity: Up to 150 TPH*

Product Introduction

Our 150 TPH Rock Jaw Crusher is a heavy-duty, high-performance machine engineered for reliable primary crushing in demanding mining, quarrying, and aggregate production environments. Designed to deliver a consistent output of 150 tonnes per hour, this crusher is the cornerstone of an efficient and profitable operation. It excels in processing hard and abrasive materials like granite, basalt, river gravel, and iron ore, reducing large-sized rocks into manageable, consistent-sized aggregates for the next stage of processing.

Built with a focus on durability, ease of maintenance, and operational efficiency, this jaw crusher ensures maximum uptime and a lower cost-per-tonne, making it an ideal investment for medium to large-scale projects.

Product Features

-

1. Robust Structure & Heavy-Duty Design:

-

The crusher frame is constructed from high-quality steel plate and reinforced with heavy-duty ribs for superior strength and longevity, capable of withstanding the toughest crushing conditions.

-

-

2. High-Efficiency Crushing Chamber:

-

The deep, symmetrical crushing chamber and optimized nip angle (the angle between the fixed and movable jaw) ensure high reduction ratios, excellent material flow, and prevents clogging, resulting in a higher capacity and a more uniform product shape.

-

-

3. Durable Jaw Plates:

-

Manufactured from high manganese steel or other advanced alloys, the jaw plates are reversible and interchangeable to maximize service life and reduce replacement costs.

-

-

4. Reliable Eccentric Shaft Assembly:

-

The oversized, forged eccentric shaft is supported by heavy-duty, spherical roller bearings, providing high load capacity and reliable performance under shock loads.

-

-

5. Easy Adjustment & Setting:

-

The closed-side setting (CSS) can be easily adjusted using hydraulic or mechanical shims, allowing for quick and precise control over the final product size without stopping the machine.

-

-

6. Safety & Easy Maintenance:

-

Features like a centrally located grease lubrication system and easily accessible service points simplify routine maintenance. Safety guards and a toggle plate that acts as a safety device in case of uncrushable material protect the crusher from severe damage.

-

-

7. Versatile Feed Opening:

-

The generous feed opening allows the crusher to accept large-sized feed material, reducing the need for primary blasting and secondary breaking.

-

Technical Parameters Table

| Parameter | Specification |

| Feed Opening | 750mm x 1060mm (30″ x 42″) |

| Max. Feed Size | 630mm (25″) |

| Closed Side Setting (CSS) Range | 75mm – 200mm (3″ – 8″) |

| Capacity | Up to 150 TPH* |

| Power | 110 kW (150 HP) |

| Weight (Machine Only) | ~ 20,000 kg (44,000 lbs) |

| Main Shaft Speed | 250 rpm |

| Overall Dimensions (LxWxH) | 2700 x 2300 x 2600 mm |

Note: Capacity is dependent on feed material size, hardness, composition, and crusher setting.

Applications & Industries

The 150 TPH Jaw Crusher is a versatile primary crusher suitable for a wide range of applications:

-

1. Mining: Primary crushing of gold, copper, iron, and other metallic ores.

-

2. Quarrying: Production of aggregates (crushed stone, sand, and gravel) for construction and infrastructure projects.

-

3. Construction & Demolition (C&D): Recycling of concrete and rubble to produce reusable aggregate.

-

4. Railway Ballast: Producing high-quality, uniformly crushed stone for railway track beds.

-

5. Industrial Applications: Crushing slag and other industrial by-products.

FAQ: 150 TPH Rock Jaw Crusher

Q1: What is the meaning of “150 TPH”?

A: TPH stands for “Tonnes Per Hour.” It indicates the crusher’s designed capacity to process up to 150 tonnes of material in one hour under specific conditions.

Q2: What kind of power source does this crusher require?

A: The crusher is typically driven by an electric motor (110 kW / 150 HP as standard). However, diesel engine options can be provided for remote sites or locations without a stable power grid.

Q3: How often does the crusher require maintenance?

A: Regular daily checks (like lubrication and visual inspections) are recommended. Major wear parts like jaw plates have a lifespan that depends on the material being crushed. Regular greasing of bearings is crucial for long-term health. A detailed maintenance schedule is provided in the operation manual.

Q4: Can it handle very hard and abrasive rocks like granite or basalt?

A: Absolutely. This crusher is specifically designed with a robust structure and high-manganese steel jaw plates to handle hard, tough, and abrasive materials effectively.

Q5: How is the final product size controlled?

A: The product size is controlled by adjusting the Closed Side Setting (CSS)—the narrowest gap between the jaw plates at the bottom of the crushing chamber. This is easily done using shims or a hydraulic system, allowing for precise control without stopping the crusher.

Q6: Do you provide installation and commissioning services?

A: Yes, we offer comprehensive technical support, including installation supervision, commissioning, and operator training to ensure your plant runs at peak performance from day one.

Inquiry

Please leave us your requirements, we will contact you soon.