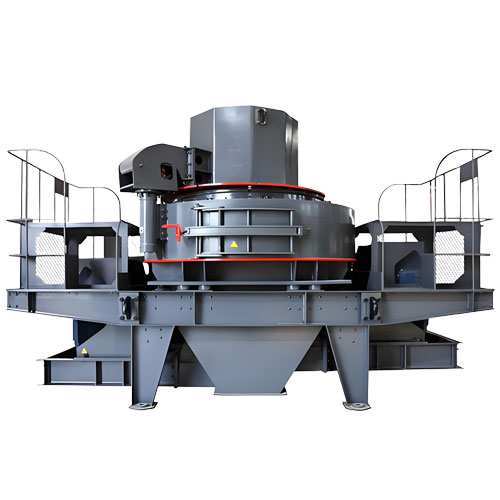

Sand making production line with an output of 1,500 tons per hour

Sand making production line is a very important piece of equipment in modern industry. It is widely used in construction materials, highways, railways, water conservancy, chemical industry and other fields. Sand Making Plant has put into use a sand making production line with a capacity of 1,500 tons, which will significantly improve the production efficiency and quality of the plant. This article will introduce the characteristics, advantages and application prospects of this sand making production line from the following aspects.

Composition and characteristics of sand making production line

The sand making production line is mainly composed of vibrating feeder, jaw crusher, impact crusher, cone crusher, vibrating screen, sand washing machine, conveyor and other equipment. The entire production line adopts closed production, which can realize a fully automated production process from raw material feeding to finished sand. This production line has the following characteristics:

1. High degree of automation: The production line adopts PLC control system throughout the entire process, achieving a high degree of automation. During the production process, only a small number of workers are needed for operation and maintenance.

2. Good stability: This production line adopts advanced hydraulic technology and electronic control technology to ensure the stability and reliability of the equipment. During the production process, there will be no equipment failures and downtime.

3. High production efficiency: The production line’s processing capacity reaches 1,500 tons per hour, which can meet the needs of large-scale production. At the same time, the processing particle size of this production line can be adjusted in a wide range and is suitable for different types of sand and gravel production.

Advantages of sand making production line

1. High-quality sand and gravel products: This production line uses advanced crushing technology and screening technology to produce high-quality sand and gravel products with stable quality, uniform fineness, low mud content, and meets national standards and construction requirements.

2. Low production cost: The equipment of this production line has low operating cost, high production efficiency and relatively low production cost. This will bring considerable economic benefits to sand making enterprises.

3. Environmental protection and energy saving: This production line adopts closed production, which can reduce noise and dust pollution. At the same time, the production line has low energy consumption and has good environmental protection and energy saving effects.

Main equipment and its working principle

The main equipment of this production line includes:

Vibrating feeder: used to supply raw materials evenly to ensure the continuity and stability of the production line.

Jaw rock crusher: used for coarse crushing of raw materials, crushing larger-sized stones into medium-sized aggregates.

Impact crusher: used for secondary crushing to further refine the stone materials into fine-grained sand and gravel products.

Cone crusher: used for crushing high hardness materials, with excellent crushing effect and wear resistance.

Vibrating screen: used to screen sand and gravel of different particle sizes to ensure that the particle size of the finished sand is uniform and meets standard requirements.

Sand washing machine: used to clean the soil and impurities in sand and gravel to ensure the high quality of the product.

Conveyor belt: connects various equipment to ensure the smooth operation of the production line.

The combination of these equipment makes the entire sand making production line efficient, environmentally friendly, automated, and able to achieve uninterrupted operation during the production process.

Production line quality control

This sand making production line not only focuses on production efficiency, but also on product quality. Through multi-layer screening and sand washing treatment, it can be ensured that the produced sand and gravel have uniform particle size, low mud content, and meet the relevant national standards for construction sand. Each batch of sand and gravel produced undergoes strict quality testing to ensure its safety and reliability in use in engineering projects.

Market demand and application prospects

1. Construction industry: With the continuous advancement of urbanization, the demand for sand and gravel aggregates in the construction industry continues to grow. The sand making production line of Sand Making Plant with an output of 1,500 tons per hour can meet the demand for sand and gravel in many fields such as large-scale construction projects, residences, bridges, highways, etc., and has broad market prospects.

2. Infrastructure construction: With the country increasing infrastructure construction, the construction of railways, highways, airports, ports and other projects also has a huge demand for sand and gravel aggregates. Efficient and stable sand making production lines will become important suppliers for major infrastructure projects.

3. Environmental protection policy: As environmental protection requirements continue to become stricter, traditional sand making production lines often cannot meet environmental protection requirements. This new production line of Sand Making Plant adopts environmentally friendly technology, reduces the emission of pollutants, complies with environmental protection policies, and adapts to market demand.

4. Regional market advantages: Henan is the transportation and logistics center in central China, rich in resources, and located in the hinterland of the construction of many key projects. This gives the sand making production line a natural geographical advantage in its application and expansion in the local market.

future development direction

After the 1,500-ton sand-making production line of the sand-making plant is put into use, it will not only greatly improve production efficiency, but also enhance market competitiveness. In the future, with the continuous advancement of technology and the increase in demand, sand making plants are likely to further expand production capacity, increase the intelligence level of equipment, and realize all-round automated operations, thereby reducing production costs and increasing profit margins.

In addition, as the concept of green environmental protection is deeply rooted in the hearts of the people, while maintaining efficient production, sand making plants will also increase investment in environmental protection to further reduce the impact on the environment and achieve sustainable development.

The putting into use of the sand making production line with an output of 1,500 tons per hour marks a major improvement of the plant in terms of technology, efficiency and environmental protection. With its high efficiency, automation and environmental protection, this production line can not only meet the current market demand for high-quality sand and gravel, but will also bring more business opportunities and competitive advantages to enterprises in future development.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.