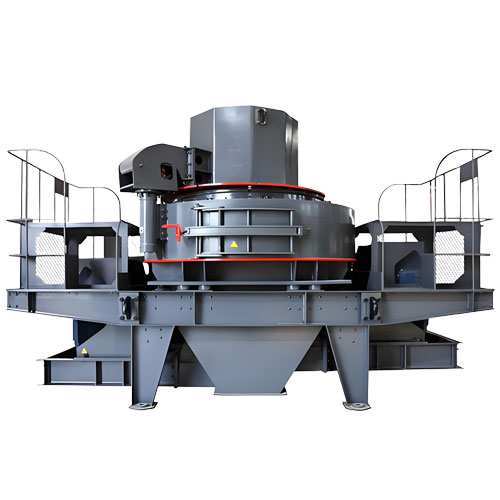

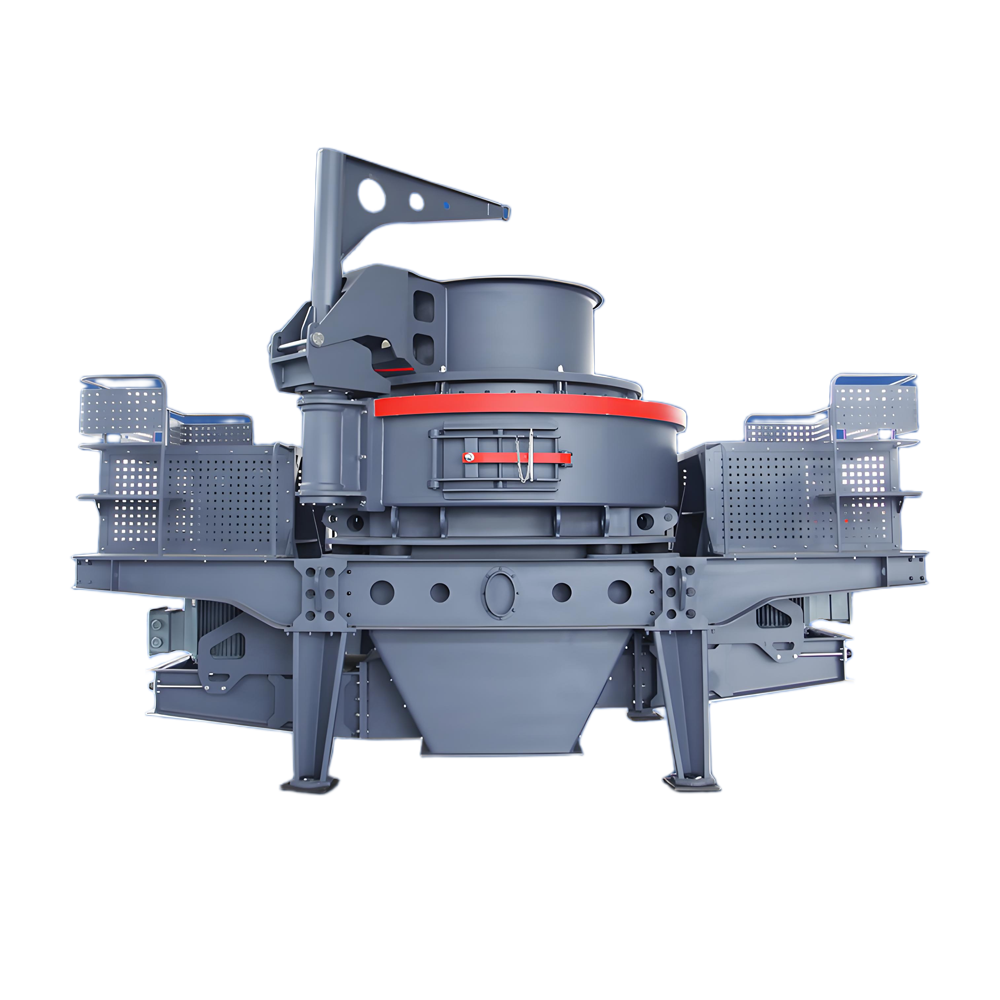

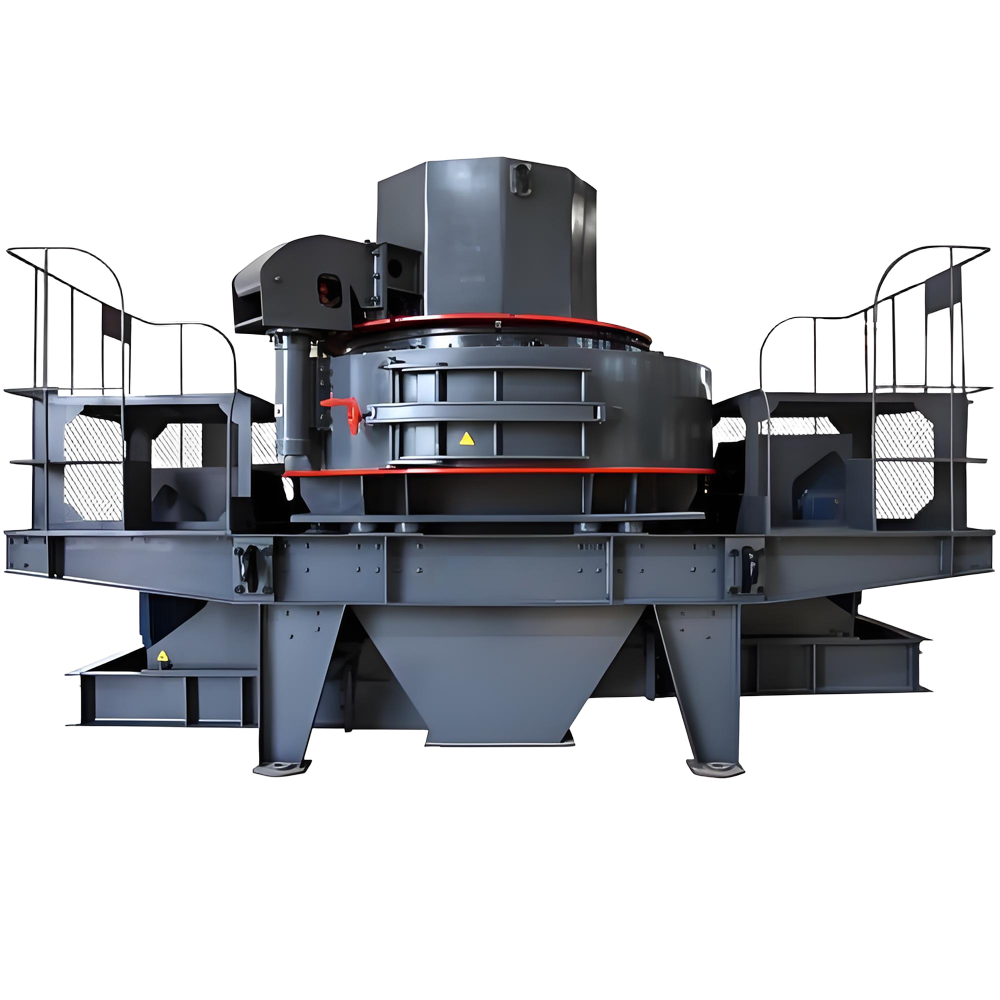

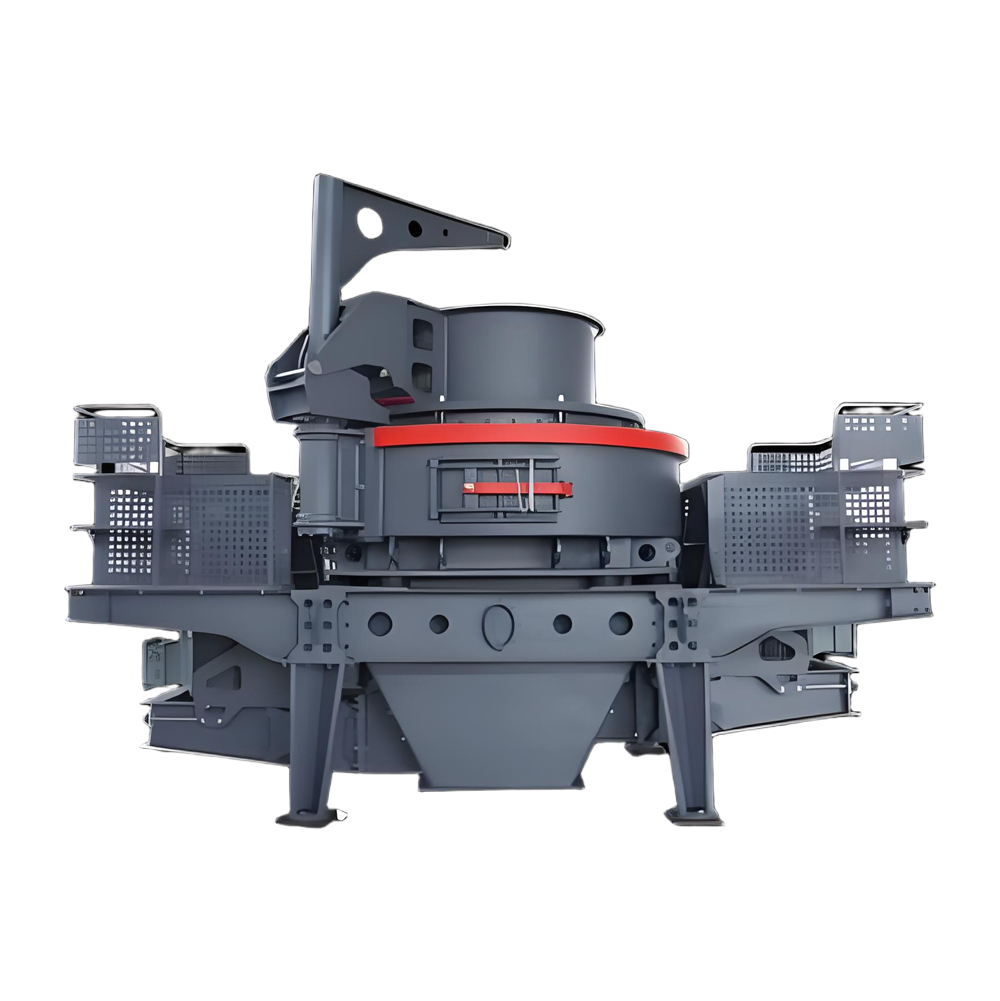

Artificial Sand Making Machine

The Artificial Sand Making Machine (also known as a Vertical Shaft Impact Crusher - VSI Crusher, Sand Maker, or Sand Making Machine) is a revolutionary piece of equipment designed to produce high-quality manufactured sand (M-Sand) from hard rocks, gravel, or industrial byproducts. It is the core technology transforming raw aggregates into perfectly graded, cubical sand particles essential for modern construction, replacing scarce and environmentally damaging natural river sand.

Feed Size: Up to 50mm (2")

Capacity: 50 - 500+ Tons Per Hour (TPH)

Rotor Speed: 55 - 85 m/s (High Speed Centrifugal Force)

Working Principle

At its heart, the machine utilizes a high-speed rotor that throws fed raw material (typically <50mm) against a crushing chamber (anvil ring or rock shelf). Impact crushing occurs through either:

-

1. “Rock-on-Rock” Principle: Material impacts against a cascade of other falling material particles, resulting in excellent particle shape and minimal wear on metal parts. Ideal for less abrasive rocks.

-

2. “Rock-on-Iron” Principle: Material impacts against metal anvils or liners within the crushing chamber, offering higher reduction ratios and suitability for highly abrasive materials. Wear parts are replaceable.

The intense impacts fracture the rock along natural cleavage lines, producing optimally shaped, cubical sand grains. The final product size is precisely controlled by adjusting rotor speed, feed rate, and the configuration of the crushing chamber/exit ports.

Key Features & Advantages

-

1. Superior Sand Quality: Produces cubical, well-graded sand particles with optimal surface texture. This significantly enhances the workability, strength, and durability of concrete and asphalt mixes compared to irregular natural sand.

-

2. High Production Efficiency: Capable of generating large volumes of sand (typically ranging from 50 TPH to 500+ TPH) consistently and reliably, meeting demanding project requirements.

-

3. Particle Shape Control: Precise adjustments allow fine-tuning of the particle shape and gradation curve, enabling production of sand tailored for specific applications (e.g., plastering sand, concrete sand).

-

4. Low Operational Costs:

- Reduced Wear: Advanced wear-resistant materials (like tungsten carbide tips, high-chrome liners) and optimized crushing principles (especially rock-on-rock) significantly extend component life.

- Energy Efficient: Modern designs optimize power consumption per ton of sand produced.

-

5. Versatility: Can process a wide range of feed materials: granite, basalt, limestone, river pebbles, quartz, diabase, iron ore, copper ore, slag, concrete waste, etc.

-

6. Environmental Sustainability:

- Conserves Natural Resources: Eliminates dependency on ecologically sensitive river sand mining.

- Waste Utilization: Can process construction demolition waste and industrial slag into valuable sand.

- Waterless Process: Unlike traditional washing, most modern sand makers produce dry, ready-to-use sand, conserving water and eliminating slurry ponds.

-

7. Low Fines Generation: Optimized crushing minimizes the production of excessive micro-fines (<75 micron), which can be detrimental to concrete quality.

-

8. Compact Design & Easy Maintenance: Modular designs facilitate installation and relocation. Critical wear parts are often designed for easy access and replacement, minimizing downtime.

-

9. Closed-Circuit Operation: Easily integrated with screening equipment to recirculate oversize material and achieve precise final product sizing.

Technical Specifications (Typical Range – Varies by Model & Manufacturer)

| Feature | Specification Range |

| Feed Size | Up to 50mm (2″) |

| Capacity | 50 – 500+ Tons Per Hour (TPH) |

| Rotor Speed | 55 – 85 m/s (High Speed Centrifugal Force) |

| Motor Power | 110 kW – 600+ kW (150 HP – 800+ HP) |

| Max Feed Size | Typically 1/3 of Rotor Diameter |

| Product Size | 0-5mm (Adjustable for specific grading) |

| Crushing Principle | Rock-on-Rock, Rock-on-Iron, Hybrid |

| Weight | 10 – 30+ Tons |

Applications of Produced Artificial Sand

-

Concrete Production: High-strength, pre-cast, ready-mix concrete.

-

Asphalt Mixes: Improves binder adhesion and mix stability.

-

Plastering & Masonry Mortars: Provides smooth finish and good workability.

-

Paver Blocks & Tiles: Essential for consistent quality and strength.

-

Industrial Flooring & Screeds.

-

Railway Ballast & Filter Media (coarser fractions).

-

Landscaping & Golf Course Construction.

Why Choose an Artificial Sand Making Machine?

-

Guaranteed Supply: Break free from unreliable natural sand sources and price fluctuations.

-

Quality Control: Produce sand with consistent properties tailored to your exact needs.

-

Cost-Effectiveness: Lower long-term operational costs vs. natural sand procurement (especially considering transport and quality issues).

-

Environmental Compliance: Meet strict regulations on river sand mining and promote sustainable construction practices.

-

Profitability: Create high-value sand from readily available local rock sources or waste materials.

The Artificial Sand Making Machine is no longer just an alternative; it’s the intelligent, sustainable, and high-performance solution for producing the construction-grade sand demanded by modern infrastructure. Investing in this technology ensures a reliable supply of superior quality sand, reduces environmental impact, and enhances the profitability and efficiency of aggregate and concrete production operations.

Ready to produce premium artificial sand? Contact us today to discuss your specific requirements and find the optimal sand making machine solution for your project!

Inquiry

Please leave us your requirements, we will contact you soon.