What is humic acid? Can it be processed with Raymond mill?

Definition and characteristics of humic acid

Humic acid is a widely occurring macromolecular organic substance in nature, primarily formed by microbial decomposition of plant and animal remains (especially plant debris) and geochemical processes. It is found in soil, coal (such as peat, lignite, and weathered coal), and water. It possesses a complex aromatic and alicyclic structure, with functional groups such as carboxyl, hydroxyl, carbonyl, and quinone attached to the rings. Due to its unique physical and chemical properties (such as ion exchange, adsorption, and complexation), humic acid is widely used in agriculture, industry, environmental protection, and medicine, among other fields. It serves as a fertilizer enhancer, soil conditioner, water treatment agent, and feed additive.

Classification of humic acid

Humic acid can be divided into different types based on solubility and source:

1. By solubility: fulvic acid (soluble in water and dilute acid), fulvic acid (soluble in acetone or ethanol), and fulvic acid (insoluble in acetone).

2. By source: soil humic acid, coal humic acid (such as extracted from weathered coal), water humic acid, etc.

3. According to the generation method: native humic acid and regenerated humic acid (generated by artificial oxidation of coal, such as nitrohumic acid).

Can humic acid be processed using Raymond mill?

Raymond mill is suitable for processing humic acid for the following reasons:

1. Applicable Materials: Raymond mills are primarily used for non-flammable and explosive materials with relatively low hardness (Mohs hardness ≤ 8) and a moisture content ≤ 6%. Humic acid feedstocks (such as weathered coal) generally meet this hardness requirement, and moisture content can be controlled through drying pretreatment.

2. Finished product fineness requirements: Raymond mills can process finished products with a fineness of 80-400 mesh. Humic acid processing often requires fine powder (such as 80-100 mesh), and Raymond mills can meet these particle size requirements.

3. Industrial application example: According to the data, the processing flow of humic acid (such as extracted from weathered coal) clearly mentions the use of Raymond mill to grind the raw materials to the required fineness, which proves its technical feasibility.

Notes and suggestions

1. Equipment selection: Traditional Raymond mills may have problems such as insufficient grinding force and substandard environmental protection. It is recommended to choose models with upgraded technology, or equipment from large manufacturers with R&D capabilities (such as Guilin Mining Machinery, which has 52 years of R&D, production and operation) to ensure high efficiency, environmental protection and durability.

2. Raw material testing: Humic acid content varies greatly from source to source. Before processing, professional testing (such as the Shanxi Taiyuan Humic Acid Testing Center) is required to determine the purity of the raw materials in order to optimize process parameters.

3. Maintenance requirements: Humic acid has strong hygroscopicity, so the equipment needs to pay attention to sealing and lubrication (such as bearing maintenance) to avoid blockage or corrosion caused by humidity.

4. Environmental protection measures: A dust removal system must be configured during the processing to prevent dust pollution.

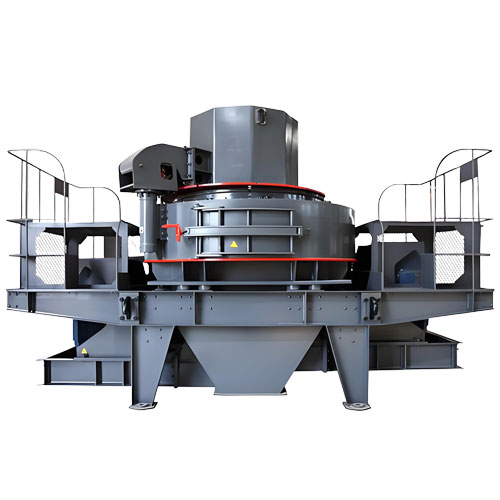

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.