What is a cone crusher?

In the world of aggregate production, mining, and quarrying, the goal is simple: take big rocks and turn them into smaller, usable ones. While several types of crushers exist, one of the most crucial and efficient is the cone crusher.

If you’ve ever wondered how the sand, gravel, and crushed stone for construction and roads are made, you’re about to find out. Let’s dive into what a cone crusher is, how it works, and why it’s a cornerstone of modern industry.

The Core Concept: What is a Cone Crusher?

At its simplest, a cone crusher is a machine that uses a gyrating spindle (or “mantle”) inside a concave hopper (or “bowl liner”) to compress and break large rocks into smaller pieces. Think of it as a highly efficient, industrial-grade nutcracker, but for rocks.

It’s primarily used for secondary, tertiary, and quaternary crushing stages. This means it takes the larger pieces that have already been broken down by a primary jaw crusher and reduces them further to precise, fine-sized aggregates.

How Does a Cone Crusher Work? The Magic is in the Motion

The operation of a cone crusher is elegant in its principle but powerful in its execution. Here’s a step-by-step breakdown:

- 1. Feed: Rocks are fed into the top of the crusher through a hopper.

- 2. Crushing Chamber: The rocks fall into the space between the rotating mantle and the stationary bowl liner. This space is the crushing chamber.

- 3. Gyrating Action: The mantle gyrates (a kind of wobbling, eccentric rotation) against the bowl liner. Unlike the simple up-and-down motion of a jaw crusher, this gyrating action continuously compresses and crushes the rock against the bowl walls.

- 4. Progressive Crushing: As rocks travel downward through the chamber, they are crushed multiple times, becoming progressively smaller. This ensures a consistent and well-shaped end product.

- 5. Discharge: The now-crushed material exits at the bottom of the crusher through the gap between the mantle and the bowl liner, known as the Closed Side Setting (CSS). The CSS is a critical adjustment that directly controls the size of the final product.

Key Components of a Cone Crusher

To understand it better, let’s look at its main parts:

- 1. Mantle: The moving, gyrating part that does the crushing. It’s the “head” of the spindle.

- 2. Bowl Liner: The stationary, concave surface that the mantle crushes the rock against.

- 3. Eccentric Assembly: The mechanism that causes the mantle to gyrate instead of just spin.

- 4. Main Shaft: The central shaft that the mantle is attached to.

- 5. Hydraulic System: Used for adjusting the CSS, clearing blockages, and providing overload protection.

Why Choose a Cone Crusher? Key Advantages

Cone crushers are favored for several compelling reasons:

- 1. High Efficiency and Productivity: They handle hard, abrasive materials with less effort than many other crusher types.

- 2. Excellent Product Shape: The progressive compression crushing action produces well-shaped, cubical end products, which is essential for high-quality concrete and asphalt.

- 3. Versatility: With adjustable settings, they can produce a wide range of product sizes, from coarse aggregates to fine sand.

- 4. Reliability and Durability: Built with robust materials, they are designed for long-term, heavy-duty operation.

- 5. Automation: Modern cone crushers often come with advanced automation systems that optimize performance, protect the machine from damage, and provide real-time data.

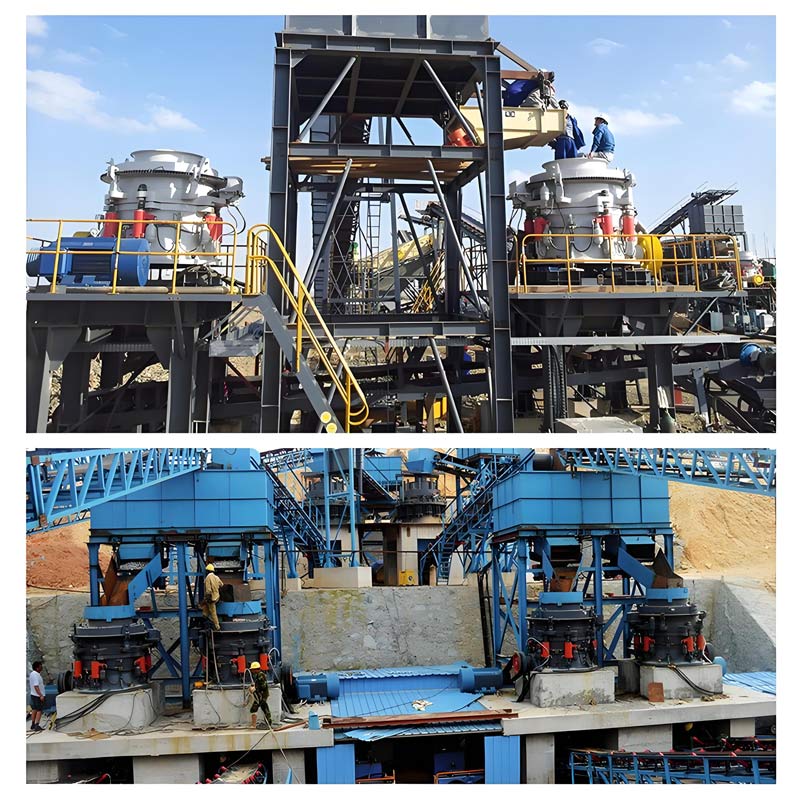

Applications: Where You’ll Find Cone Crushers

Cone crushers are workhorses in a variety of industries:

-

Mining: Crushing ore to extract precious minerals like copper, gold, and iron.

-

Aggregate Production: Creating crushed stone, sand, and gravel for the construction industry.

-

Quarrying: Processing rock extracted from quarries.

-

Recycling: In some cases, they are used for crushing demolition concrete and asphalt.

Hydraulic vs. Spring Cone Crushers

There are two main types:

-

Spring Cone Crushers: An older design that uses springs for overload protection. They are simpler but less adjustable and efficient.

-

Hydraulic Cone Crushers: The modern standard. They use hydraulic systems for all adjustments and protection, offering greater control, safety, and efficiency. Most new models on the market are hydraulic.

Conclusion

The cone crusher is more than just a piece of machinery; it’s a vital component that drives the infrastructure of our modern world. Its unique combination of efficiency, reliability, and the ability to produce high-quality, spec material makes it an indispensable tool in turning raw rock into the building blocks of our cities and technologies.

Whether you’re a seasoned professional in the industry or just curious about how things are made, understanding the cone crusher provides a fascinating glimpse into the hard work that happens behind the scenes.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.