Technical Analysis of Core Equipment for High Calcium Stone Grinding

The GK series Raymond mill increases production capacity by 30%-40%, takes up less space, and consumes less energy. The vertical mill is environmentally friendly and quiet, making it suitable for urban areas. The ultrafine mill achieves submicron fineness while reducing energy consumption by 30%. From coarse to ultrafine powders, our one-stop solution meets the needs of industries across building materials, chemicals, pharmaceuticals, and more.

1. Coarse powder processing (80-400 mesh)

● Equipment selection: Raymond mill (GK series upgraded version recommended)

○ Technical features:

■ Vertical structure, small footprint and low energy consumption;

■ The fineness of the finished product is adjustable (80-400 mesh), suitable for desulfurization agents, concrete admixtures, glass raw materials, etc.

■ Using pendulum grinding technology, the production capacity is increased by 30%-40% compared with traditional equipment, which is efficient and stable;

■ Strong earthquake resistance, easy maintenance, suitable for large-scale production.

○ Applicable scenarios: building materials, steel desulfurization, basic industrial fillers.

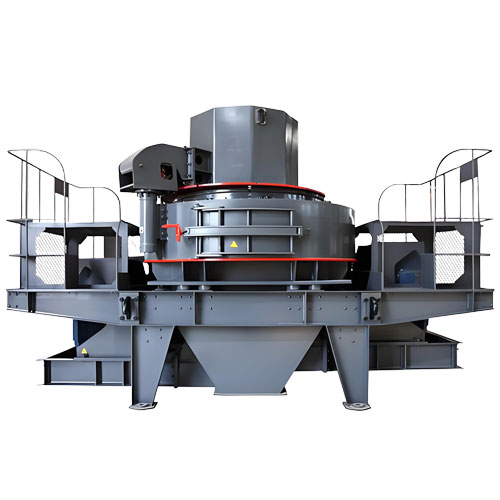

2. Medium-fine powder processing (200-600 mesh)

● Equipment selection: Vertical grinding mill (GKLM series)

○ Technical features:

■ Full negative pressure operation, sealed system, low dust emission and excellent environmental performance;

■ Low vibration and noise, suitable for urban areas or areas with high environmental protection requirements;

■ Wide production capacity range (5-700t/h), capable of processing high hardness materials (Mohs hardness ≤ 7);

■ Integrated grading system, the finished product has uniform fineness, suitable for cement and chemical raw material production.

○ Applicable scenarios: cement manufacturing, glass ingredients, industrial calcium salt production.

3. Ultrafine powder processing (325-2500 mesh)

● Equipment selection: Ultrafine vertical grinding mill/roller grinding mill

○ Technical features:

■ Achieve submicron fineness to meet the needs of high value-added fields (such as pharmaceuticals and cosmetic fillers);

■ Multi-stage classification system to effectively control particle size distribution;

■ High efficiency and energy saving, energy consumption is reduced by more than 30% compared with traditional air jet mill;

■ Wear parts are made of wear-resistant materials to extend the life of the equipment.

○ Applicable scenarios: high-end coatings, plastic modification, feed additives, and precision ceramic raw materials.

4. Special process equipment (high temperature calcination + grinding integration)

● Applicable scenarios: calcium oxide (quicklime) production.

○ Process: raw materials → crushing → high temperature calcination → cooling → grinding → grading and packaging.

○ Equipment combination: vertical kiln/rotary kiln + Raymond mill/vertical mill.

○ Advantages: Calcination and grinding are linked to reduce energy consumption in the intermediate links. It is suitable for scenes requiring calcium oxide, such as building materials and environmental desulfurization.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.