Safety operating procedures for production of active heavy calcium

Before starting the equipment, the protective devices must be checked, and it is strictly forbidden to touch the running equipment with bare hands; chemicals should be stored away from fire sources, and protective equipment should be worn during operation; the workshop should be equipped with fire-fighting facilities, and warning signs should be set up in dangerous areas – strictly follow safety regulations and protect every link of production.

Safety operating procedures (safety operating requirements for each production link)

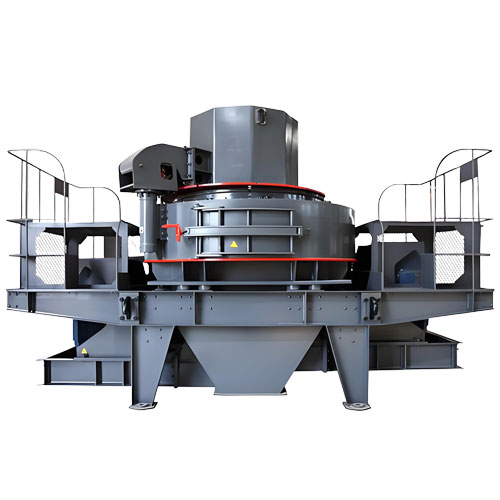

1. Raw material pretreatment and crushing and grinding stage

○ Equipment operation:

■ Before starting the equipment, check whether the safety devices such as protective covers and emergency stop buttons are intact.

■ It is strictly forbidden to directly touch the operating crushing equipment (such as jaw crusher, Raymond grinder) with your hands to prevent mechanical injuries.

■ Maintain equipment regularly to prevent material splashing and dust leakage caused by wear or malfunction.

○ Dust control:

■ Install dust removal equipment (bag dust collector, cyclone dust collector, etc.) to ensure that the dust concentration in the working area meets the standard (such as ≤8mg/m³).

■ Closed conveying system to reduce dust leakage.

○ Noise protection:

■ High-noise equipment (such as ball mills) must be equipped with sound insulation facilities, and workers must wear earplugs or earmuffs.

Modification stage

Chemical Management:

■ Modifiers (such as fatty acids, titanates) should be stored in a cool, ventilated warehouse, away from fire sources, and clearly labeled.

■ Use corrosion-resistant containers to prevent leakage or volatilization.

○ Operation Specifications:

■ Wear protective gloves and goggles when adding materials to prevent the modifier from contacting the skin or eyes.

■ Regularly check the sealing of reactors and spray equipment to prevent material splashing.

■ During the wet modification process, pH value and temperature are controlled to avoid danger caused by violent reactions.

○ Waste gas treatment:

■ The modification workshop is equipped with waste gas absorption equipment to treat volatile organic compounds (VOCs) and ensure that emissions meet standards.

Grading, crushing and packaging stage

○ Equipment security:

■ It is strictly forbidden to open the inspection port when the air flow mill or grading equipment is in operation.

■ Packaging machinery (such as automatic packaging lines) should be equipped with protective fences to prevent accidental contact with operating parts.

○ Electrostatic protection:

■ Ground the powder conveying pipeline and packaging equipment to prevent static electricity accumulation from causing dust explosion.

○ Heavy object handling:

■ Use mechanical lifting for ton bag packaging to avoid muscle strain or injury caused by manual handling.

General safety requirements

○ Firefighting facilities:

■ The workshop is equipped with fire extinguishers and fire hydrants, and fire emergency drills are conducted regularly.

○ Electrical safety:

■ The equipment is well grounded and no cables are exposed to avoid the risk of electric shock.

○ Warning signs:

■ Set up obvious warning signs in dangerous areas (such as high-temperature equipment and chemical warehouses) to indicate safety precautions.

○ Emergency Stop:

■ Each device is equipped with an emergency stop button to stop the machine and conduct inspection immediately if any abnormality occurs.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.