Large gangue grinding machine price and working principle

The price of large-scale gangue grinding mill is affected by the model, production capacity and configuration, ranging from basic models to high-end customization to meet different needs; its core is to achieve efficient crushing through crushing, grinding and grading, and is equipped with an environmental protection system to ensure clean production.

Reference for large gangue grinding mill

The price of gangue grinding mill varies greatly due to model, production capacity, configuration and supplier. The following are some large equipment for reference only:

1. Small and medium-sized equipment (basic)

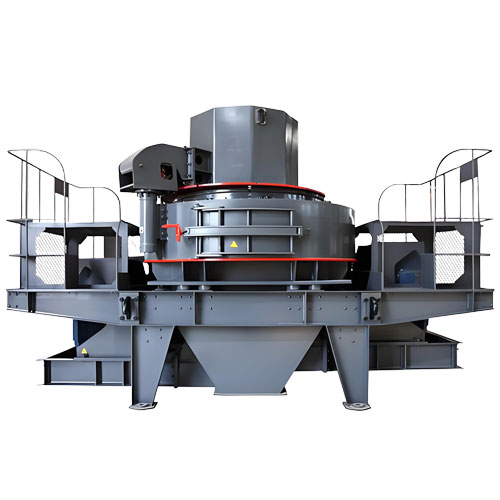

○ Examples: Vertical hammer sand making machine, small compound crusher, etc., suitable for primary crushing or small and medium-scale production.

2. Medium-sized equipment (industrial use)

○ Examples: 4R3216 Raymond mill, coal gangue vertical mill, etc., with moderate production capacity, suitable for general industrial needs.

3. Large/ultrafine grinding equipment (high-end)

○ Example: GK series grinding mills, vertical grinding mills, roller mills, etc., with high production capacity, adjustable fineness, environmentally friendly configuration, etc., are suitable for large-scale fine processing.

Factors affecting price

● Model and capacity (such as processing volume, finished product fineness);

● Equipment configuration (whether it includes dust removal system, intelligent control, wear-resistant materials, etc.);

● Brands and suppliers (differences in technology and after-sales service between different manufacturers);

● Customized requirements (special materials, production line matching, etc.).

Suggestion: For specific quotations, please contact the supplier to customize the plan based on material characteristics, production capacity requirements, site conditions, etc.

Working principle diagram and description of coal gangue grinding machine

1. Working principle and process:

Large coal gangue → Crusher (crushed to appropriate particle size) → Elevator → Silo

Vibrating feeder → Main grinding chamber (grinding roller and grinding ring) → Analyzer classification

Qualified fine powder → cyclone powder collector → finished product collection

Unqualified coarse powder → return to the main machine for re-grinding

Waste gas treatment: The remaining air is purified and discharged through a bag dust collector

2. Detailed working principle description:

● Stage 1: Crushing and conveying

The large pieces of coal gangue are crushed into small particles of 15-50mm by jaw crusher or hammer crusher and sent to the silo by elevator.

● Phase 2: Grinding (core link)

○ The material enters the grinding chamber of the main machine evenly, and the grinding roller presses the grinding ring tightly under the action of the high-pressure spring, and grinds the material into powder through rotation and rolling.

○ The scraper in the grinding chamber pushes the material between the grinding roller and the grinding ring, and uses centrifugal force and mechanical pressure to achieve efficient crushing.

● Phase 3: Classification and Collection

○ The ground powder enters the analyzer with the air flow, and the impeller rotates to produce air flow classification: the coarse material falls back to the re-grind, and the qualified fine powder enters the cyclone powder collector with the air flow.

○ The finished powder is discharged through the pipeline and collected, packaged or transported to the storage silo.

● Environmental protection and recycling system

○ Equipped with bag dust collector to filter dust and ensure that emissions meet standards;

○ Part of the airflow is recycled to reduce energy consumption and maintain negative pressure in the mill (to avoid dust overflow).

Key component functions

● Main machine: core grinding unit, including grinding roller, grinding ring and pressurizing device;

● Analyzer: adjusts the fineness of the finished product and controls the classification accuracy through the rotation speed;

● Blower: provides circulating airflow power to drive the flow of materials;

● Dust collector: environmentally friendly purification to ensure cleanliness of the workshop.

Note: The working principle diagram can be further refined. The specific structure varies slightly depending on the equipment model (such as Raymond mill, vertical mill, etc.). It is recommended to refer to the technical information provided by the supplier.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.