Industrial solid waste grinding equipment helps industry development

Industrial solid waste grinding equipment, with its high efficiency, energy savings, and environmentally friendly design, transforms waste residue into high-value-added resources, pushing solid waste treatment from “end-of-pipe treatment” to “resource recycling.” Driven by policy, the industry is entering a multi-billion-yuan blue ocean, where technological innovation and policy resonance are reshaping the solid waste industry landscape.

With rising global environmental awareness and the deepening of sustainable development concepts, my country is continuously strengthening its policies in the field of solid waste treatment, pushing solid waste resource utilization to a new level. As a key technical equipment for solid waste treatment, industrial solid waste grinding equipment, with its advantages of high efficiency, energy saving, and environmental protection, is becoming a key engine for solving solid waste problems and promoting the green transformation of the industry.

Policy-driven: Solid waste treatment enters an era of “strong regulation”

In recent years, a flurry of solid waste management policies have been introduced at the national level, injecting strong momentum into the industry. In September 2020, the revised “Law on the Prevention and Control of Environmental Pollution by Solid Waste” was officially implemented. By increasing penalties, implementing a “double penalty system,” and raising the cost of violations, the revised law is forcing companies to strengthen their compliance with solid waste handling regulations. For example, the new law increases fines for non-compliant companies to 10-20 times the original standards and includes them in the public disclosure of credit records, forcing companies to shift from passive pollution control to proactive environmental protection. Against this backdrop, the solid waste treatment industry chain has experienced explosive growth, and demand for industrial solid waste grinding equipment has surged significantly.

Technological breakthrough: Industrial grinding equipment reshapes the solid waste value chain

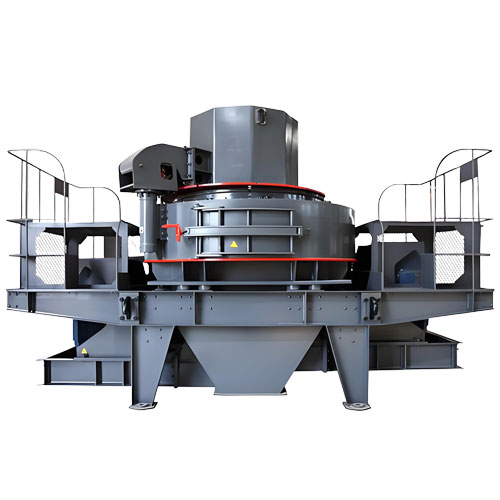

Industrial solid waste grinding equipment transforms waste residue into high-value-added resources through crushing and grinding technologies, achieving the goal of “turning waste into treasure.” New equipment, represented by GKLM vertical grinding mills and ultrafine grinding equipment, possesses several core technological advantages:

1. High efficiency and energy saving: The integrated drying-grinding process reduces energy consumption by 30%-50% compared with traditional equipment, significantly reducing processing costs;

2. Fine processing: It can grind steel slag, slag, construction waste, etc. to micron-level fineness, broadening the application field;

3. Environmentally friendly design: The closed structure is equipped with a dust removal system, and the dust emission concentration is lower than the national standard, eliminating secondary pollution;

4. Multi-material adaptability: Compatible with complex materials such as wet-process discharged slag and high-hardness construction waste, improving resource utilization.

Application scenario: From “end-of-life processing” to “resource recycling” practice

Industrial solid waste grinding equipment has penetrated into multiple fields, forming a diversified application ecosystem:

1. Building materials industry: Slag and steel slag can be ground into cement admixtures and concrete additives, replacing some cement raw materials and reducing carbon emissions.

2. Road engineering: Electric furnace slag powder is used as road base material to improve road bearing capacity and durability;

3. Circular agriculture: Grinding waste residue into slag fertilizer to enhance soil nutrients;

4. High value-added products: By extracting valuable components from tailings or preparing new building materials such as expanded clay and permeable bricks, the value of the industrial chain can be extended.

A typical example is that a steel company used grinding equipment to increase the utilization rate of electric furnace slag to 90%, saving more than 10 million yuan in annual costs; the silicon-based solid waste lightweight microcrystalline stone project achieved an 80% comprehensive utilization rate of solid waste, promoting the green upgrade of the building materials industry.

Market prospects: Technological innovation and policy resonance give rise to a blue ocean worth hundreds of billions of yuan

According to the “2024-2029 China Ultrafine Grinding Equipment Industry Market Analysis and Development Prospect Forecast Report”, the industry market size continues to expand, with a compound growth rate of XX% from 2019 to 2023. The future trend shows three major characteristics:

1. Intelligent upgrade: The equipment will integrate AI control and IoT monitoring to achieve real-time optimization of operating parameters and further improve efficiency;

2. Multidisciplinary integration: Cross-innovation in materials science, mechanical engineering, and environmental protection technologies to develop more efficient grinding processes;

3. Regional demand differentiation: Demand has surged in industrially concentrated areas such as East China and North China, and customized equipment services have become a new trend.

At the policy level, the “14th Five-Year Plan” clearly requires a solid waste resource utilization rate target, and adds supporting measures such as garbage classification and cross-provincial transfer management of hazardous waste to build a solid guarantee for the long-term development of the industry.

Challenges and Prospects: Collaborative Innovation is the Key to Steady Progress

Despite the promising prospects, the industry still faces challenges such as high initial equipment investment and inconsistent technical standards. Future efforts require strengthened collaboration between industry, academia, and research to promote the development of low-cost, high-performance equipment. Simultaneously, improvements must be made to solid waste classification standards and regulatory systems to streamline the entire “production-treatment-use” chain. Only through the coordinated efforts of policy, technology, and the market can the qualitative leap from “reduction” to “value-added” in solid waste treatment be achieved.

Environmentally friendly solid waste treatment is not only a rigid requirement for ecological protection but also a strategic opportunity for the development of a circular economy. Industrial solid waste grinding equipment, with its technological innovation and resource conversion capabilities, is reshaping the industry landscape, providing solid support for the development of ecological civilization and the transition to a green economy. In this wave of solid waste revolution, the combined force of technological innovation and policy guidance will undoubtedly forge a sustainable and win-win path.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.