How much does a 120-ton-per-hour road and concrete crusher (model 69) cost?

In modern urban infrastructure construction, various types of crushed stone are used in many places. This refers to angular aggregates formed by processing rocks that meet project requirements. Generally, crushed stone for concrete is divided into 5-16mm crushed stone (commonly known as “melon seed chips”), 5-25mm crushed stone (commonly known as “1-2 stones”), and 16-31.5mm crushed stone (commonly known as “1-3 stones”). Of course, in actual highway engineering, different specifications of stones are required depending on the specific purpose.

What types of 69 stone crushers are available with a capacity of 120 tons per hour and are used for producing aggregate for highways and concrete?

Traditional 69 Jaw Crusher

This refers to a jaw crusher with a feed opening of 600*900 mm. It is a commonly used primary crushing equipment. Due to its low investment cost, large crushing ratio, and expected output of up to 180 tons, it is very popular among users in various regions.

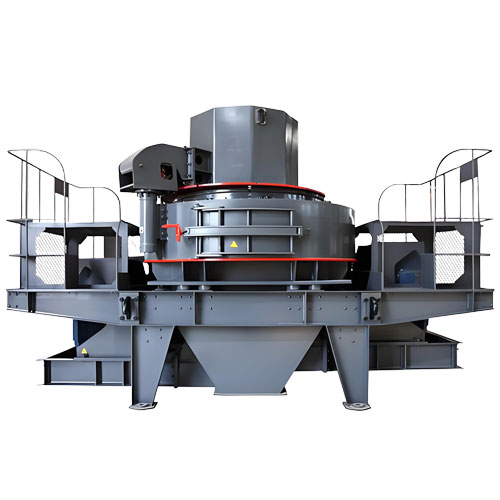

The New Generation Mobile 69 Crusher

This is a new type of mobile crushing equipment consisting of a stationary 69 crusher and a tire- or tracked (selected according to actual needs) chassis. In recent years, due to stricter domestic environmental protection requirements and its inherent convenience and applicability, many stone production plants have chosen it. Compared with stationary crushers, in addition to meeting the original requirements for feeding, output, and finished products, it also has its own outstanding features—better energy-saving and environmentally friendly performance, better adaptable to modern engineering needs; strong mobility, adaptable to various complex terrains; and the ability to be moved according to the degree of raw material mining, making it convenient and worry-free.

How much does a 120-ton-per-hour road and concrete 69mm crusher cost?

The price of a traditional 69mm crusher and a mobile 69mm crusher differs due to differences in configuration, production requirements, materials used, and technology employed. In terms of purchase price alone, a mobile 69mm crusher is more expensive. However, it saves a significant amount of money on the foundation construction for a fixed crusher, and it can be moved and reused at any time, making it relatively more cost-effective.

As for the price of a 120-ton-per-hour road and concrete 69 stone crusher, it depends on your raw material properties, finished product requirements, site size, and other factors. Our product manager will provide you with a specific configuration and quote. You can consult our customer service online for free or call our 24-hour hotline.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.