Factors affecting the normal production of sand and gravel crushers

Various types of crushers are used in sand and gravel production. However, crushers inevitably encounter various problems during operation. These problems can easily lead to equipment malfunctions and production interruptions, as well as damage or even permanent destruction of the crushing equipment, failing to achieve the initial purpose of the investment. This article discusses the factors affecting the normal production of a new type of mobile sand and gravel crusher and provides solutions.

Factor 1: Temperature

During operation, each component of the new mobile sand and gravel crusher has an optimal operating temperature. First, it’s crucial to prevent overloading the equipment at low temperatures and ensure normal operation during the low-speed preheating phase. Allow the machine to reach the specified temperature before driving or operating it; don’t underestimate its importance just because no immediate problems arise. Second, prevent the equipment from operating at high temperatures. Regularly check the readings on various temperature gauges during operation. If any problems are found, immediately stop the machine for inspection and troubleshooting. Never allow the equipment to operate while malfunctioning. If the crusher has a temperature control system, such as the cooling system of a water-cooled machine, check and add cooling water before daily operation. For air-cooled machines, regularly clean the dust from the air-cooling system to ensure unobstructed airflow.

Factor Two: Impurities

Mechanical impurities generally refer to non-metallic substances such as dust and soil, as well as metal shavings and wear products generated by the crusher during operation. Once these impurities enter the crusher, they can cause significant damage: accelerating wear on parts, scratching equipment surfaces, disrupting the lubricating oil film, increasing part temperature, and deteriorating the lubricating oil. Measurements show that when the mechanical impurities in the lubricating oil increase to 0.15%, the wear on the first piston ring of an engine will be 2.5 times greater than normal; and when impurity particles enter rolling bearings, their lifespan will decrease by 80% to 90%. Therefore, it is essential to protect new mobile sand and gravel crushers operating in harsh environments from various impurities entering their interiors. When equipment malfunctions and requires repair, it is also crucial to prevent impurities and dust from entering the equipment.

Factor Three: Corrosion

Corrosion refers to the chemical or electrochemical reaction between a metal surface and its surrounding medium, causing the equipment to become corroded. Once corrosion occurs, it not only affects the normal operation of the mobile sand and gravel crusher but also corrodes internal components. For example, rainwater and chemicals in the air can enter the machine through external channels and gaps in the components, corroding internal parts, accelerating wear, and increasing the risk of malfunctions. During the use of the crusher, management and operators must take effective measures based on specific weather conditions and air pollution levels to prevent chemical corrosion, especially preventing rainwater and corrosive chemicals in the air from entering the machine.

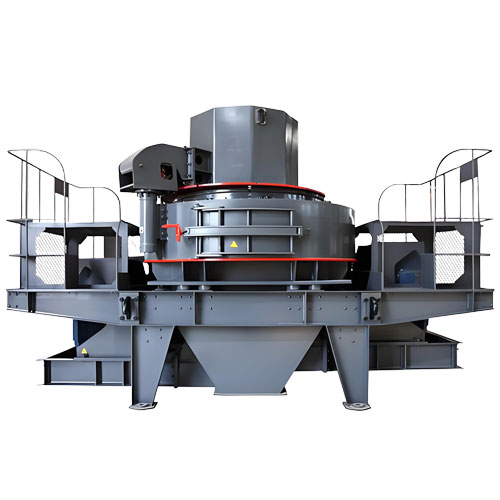

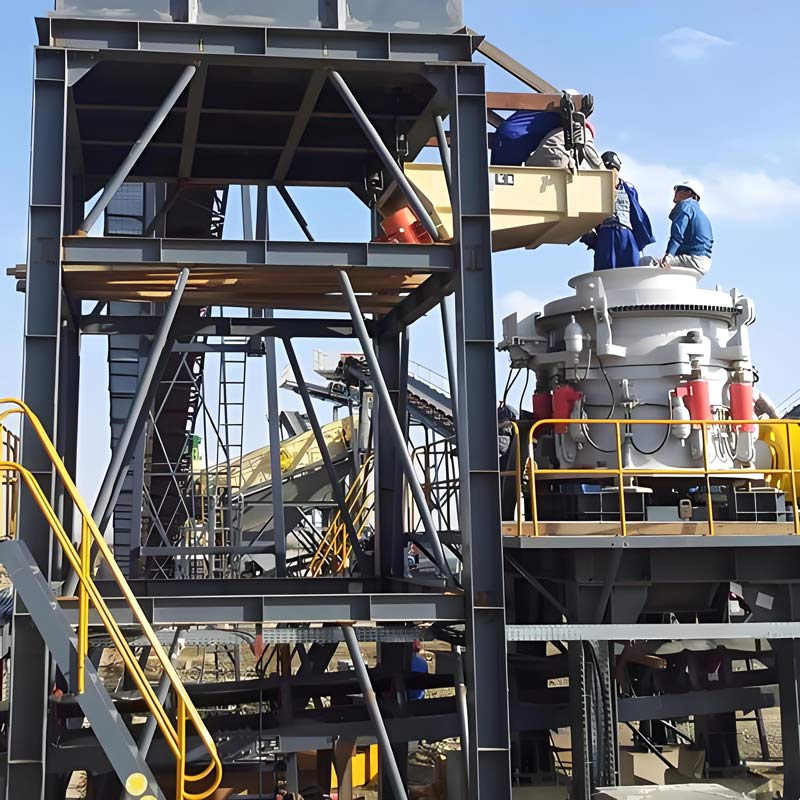

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.