Equipment failure rate of large gangue grinding machine

Standardized maintenance can reduce the failure rate to 1%-3%. The key lies in regular inspections, lubrication management, operator training and the use of high-quality accessories to prevent small problems from turning into big losses.

Maintenance recommendations to reduce failure rates

● Regular maintenance: Develop a maintenance plan, check key components (bearings, seals, wearing parts) monthly, and perform a comprehensive overhaul every quarter.

● Lubrication management: Replace lubricating oil regularly according to the equipment manual to keep bearings and gears well lubricated.

● Material pretreatment: Control the particle size of the material entering the mill (not exceeding the equipment requirements) to prevent metal impurities from entering the mill.

● Operation training: Provide training to operators to avoid overload operation or illegal operation.

● Accessory quality: Use original or high-quality replacement parts to avoid malfunctions caused by poor quality accessories.

● Environmental control: Keep the workshop ventilated and dry to reduce the impact of dust on electrical components.

Maintenance costs and spare parts reserves

● Common spare parts: It is necessary to stock up on wearing parts (grinding rollers, grinding rings, sealing rings, belts, bearings, etc.) and consumables (lubricating oil, sealing gaskets).

● Maintenance cost: The cost of routine minor repairs is relatively low (hundreds to thousands of yuan), while the cost of replacing core components (such as a complete set of grinding rollers) is relatively high (thousands to tens of thousands of yuan), depending on the equipment model.

Special reminder

● Some faults (such as bearing overheating and abnormal vibration) may indicate larger problems and require timely shutdown and inspection to avoid damage to the main engine.

● When the equipment is shut down for a long time, it needs to be treated with rust prevention and run idle regularly to prevent components from getting stuck.

Failure rate data reference (based on industry experience, not absolute values)

● The monthly downtime rate of high-quality equipment under standardized maintenance is about 1%-3%;

● For equipment that lacks maintenance, the failure rate may rise to 10%-20%, and the maintenance cost will increase significantly.

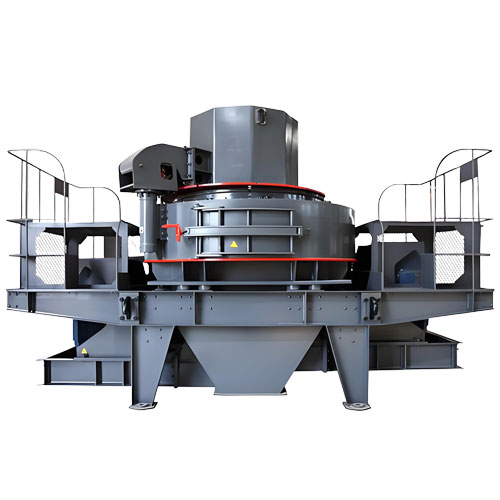

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.