Cement plant coal slag grinding participates in raw material batching

Under the “dual carbon” goal, Guangling Jinyu Cement innovatively adopted coal slag grinding technology. Through three-stage pretreatment and vertical mill system optimization, it achieved an 18.3% reduction in raw material costs and an annual reduction of 128,000 tons of CO emissions. Every 10,000 tons of coal slag utilization can reduce dust emissions by 3.6 tons, and the potential market for technology promotion reaches 4 billion yuan.

introduction

Driven by the “dual carbon” goals, the cement industry is undergoing a critical transition from traditional production models to green, low-carbon ones. The comprehensive utilization of coal slag, a solid waste left over from coal combustion, is not only crucial for environmental improvement but also a key breakthrough for companies to reduce costs and increase efficiency. This article, using the practical experience of Guangling Jinyu Cement Co., Ltd. as an example, analyzes the technical path and economic and ecological benefits of coal slag grinding in raw meal batching.

1. Coal slag characteristics and pretreatment technology

1.1 Physical and chemical properties of coal slag

Coal ash is primarily composed of SiO (40%-60%), AlO (20%-35%), FeO (5%-15%), and unburned carbon. Its grindability (5.1-18.9 kWh/t) lies between that of limestone and clay. Wet coal ash can have a moisture content of 20%-30%, requiring drying to reduce the moisture content to below 8% to prevent adhesion during grinding.

1.2 Pretreatment process innovation

Adopt “three-stage” treatment process:

Crushing and screening: jaw crusher crushes large pieces of coal slag into pieces less than 25mm

Drying quality improvement: Rotary dryer utilizes waste heat from kiln exhaust to achieve energy saving and consumption reduction

Homogenization storage: The circular homogenization storage uses multi-point material extraction technology to ensure ingredient stability

2. Optimization of coal slag grinding system

2.1 Grinding equipment selection

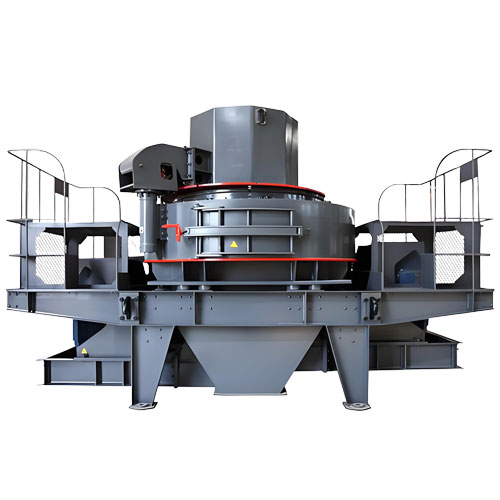

Practice has shown that vertical mill final grinding systems (such as the large vertical mill for raw materials from Guilin Mining Machinery) save over 30% more energy than ball mills. Their specially designed rollers and grinding discs separate the grinding area into coarse and fine grinding zones, keeping system power consumption below 13.81 kWh/t. For wet slag processing, a combined roller press and drying mill grinding system can be configured to achieve dual control of moisture content and particle size.

2.2 Granularity Control Key

Coal slag grinding needs to meet the following requirements:

Specific surface area ≥350m²/kg

0.08mm sieve residue ≤8%

Particles below 20μm account for ≥65%

By adjusting the speed of the powder selector and the wind speed in the mill, the particle size distribution can be accurately controlled to avoid over-grinding.

3. Innovation in raw material batching process

3.1 Application of Intelligent Batching System

A dual-detection system using a fluorescence analyzer and a neutron activation analyzer, combined with a Python algorithm, builds a time-series rolling regression prediction model. The system can correct deviations in the three rates (KH, SM, and IM) in real time, increasing the batching qualification rate from 45% to 92%. Application on a 5,000 t/d production line has resulted in annual savings of 2,400 tons of standard coal and reductions of 18,000 tons of CO₂.

3.2 Optimization model of coal slag content

The dosage prediction equation was established through orthogonal experiment:

Y=0.72X₁+0.45X₂-0.31X₃+1.28 (X₁: coal slag content, X₂: limestone ratio, X₃: iron raw material ratio)

Practice has shown that when the slag content is controlled at 8%-12%, the raw meal is most burnable and the 28-day compressive strength of the clinker can reach 57.5MPa.

4. Economic and Ecological Benefit Analysis

4.1 Cost-effectiveness comparison

Index of traditional coal slag utilization process reduction

Raw material cost 120 yuan/t 98 yuan/t 18.3%

Comprehensive power consumption 22kWh/t 17.5kWh/t 20.5%

CO₂ emissions 865kg/t 712kg/t 17.7%

4.2 Environmental Benefit Assessment

Every 10,000 tons of coal slag used can reduce:

The storage area is about 1.2 acres

Dust emissions: 3.6 tons

Sulfur oxide emissions: 18 tons

Guangling Jinyu Cement uses 150,000 tons of coal slag annually, which is equivalent to reducing CO₂ emissions by 128,000 tons and creating environmental benefits of more than 20 million yuan.

5. Industry Application Prospects

5.1 Technology Promotion Value

This technology is suitable for:

Coal-fired power regional cement plant

Areas rich in industrial waste slag resources

Key areas with strict environmental protection requirements

According to statistics, the national cement industry consumes more than 80 million tons of coal slag annually, and the potential market space reaches 4 billion yuan.

5.2 Policy support opportunities

In compliance with the requirements of the “14th Five-Year Plan for Circular Economy Development”, you can enjoy:

70% VAT refund

Environmental protection electricity price will be increased by 0.03 yuan/kWh

Green building material certification bonus

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.