Basic process of high calcium stone deep processing and grinding

The processing of high-calcium stone powder starts from crushing and screening to high-temperature calcination, and then undergoes precision grinding and grading to remove impurities, ultimately producing high-purity powder with a mesh size of 80-2500. The whole process is controlled to ensure consistent quality.

The processing of high calcium stone powder usually involves the following core links:

1. Raw material pretreatment

The high-calcium ore raw materials need to be crushed and screened to crush the large pieces of ore into a particle size suitable for the grinding mill feed (usually 30-50mm), remove impurities, and ensure the subsequent grinding efficiency.

2. High temperature calcination (some application scenarios)

To produce high-calcium calcium oxide (CaO), the raw materials are calcined in a furnace at high temperatures (approximately 900-1200°C) to decompose into calcium oxide and carbon dioxide. This step is commonly used in the production of desulfurization agents and building materials.

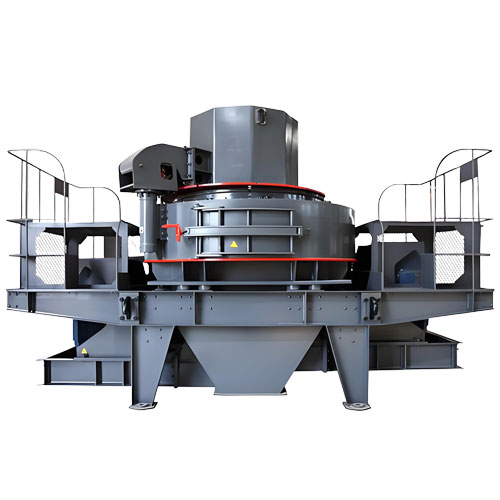

3. Grinding

The core step is to grind the raw materials to the target fineness through the grinding equipment. Different equipment can be selected according to the fineness requirements, and the common range covers 80-2500 mesh.

4. Grading and impurity removal

Use grading equipment to separate powder that meets the fineness requirements, while removing impurities such as iron and silicon to improve product purity.

5. Packaging and storage

The finished powder is sealed and packaged to prevent moisture absorption or contamination, making it easy to transport and use.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.