Analysis of the advantages of vertical grinding mill for slag

As a byproduct of blast furnace ironmaking, slag plays a vital role in cement, concrete, and building materials due to its unique granulated foam structure and active ingredients. Vertical mill technology significantly improves slag grinding efficiency through a highly efficient bed grinding and classification system, reducing energy consumption by over 30% compared to traditional equipment, achieving high-value resource utilization and green production.

1. Overview of slag

1.1 Source and composition of slag

Slag, an industrial byproduct, is a result of the complex process of ironmaking in blast furnaces. Inside the blast furnace, raw materials like iron ore and coke undergo a vigorous chemical reaction at high temperatures, melting them to produce the molten iron we need. Slag is a byproduct of this process.

When the molten slag in the blast furnace is discharged, it needs to undergo special treatment to form slag. Currently, there are two main treatment methods: slag pool water quenching and furnace-front water quenching. Slag pool water quenching is a more traditional method of pouring the slag into a pool of water far away from the blast furnace. After quenching, the slag is removed by crane. In furnace-front water quenching, a special slag flushing device is installed near the blast furnace taphole. This allows the slag to directly contact water as it flows out, rapidly cooling it to form granular slag. This method is more efficient and easier to mechanize.

Slag is primarily composed of gangue, fuel ash, and flux. Gangue refers to components other than iron in iron ore, such as silica, that are not reduced during the ironmaking process and remain molten in the slag. Fuel ash is the solid residue left after the combustion of fuels such as coke. Fluxes, such as limestone, are typically added to lower the melting point and improve the fluidity of the slag. These components fuse together at high temperatures and, after rapid cooling, form the unique granulated foam structure of slag.

At a microscopic level, slag particles have a rough, porous surface and a light, brittle texture. This structure makes them easily grindable, making them easy to process into fine powder. Slag is typically milky white, giving it a soft and brittle appearance. In the metallurgical industry, slag, due to its unique properties and source, has become a valuable resource, widely used in various fields.

1.2 Physical and chemical properties of slag

As an industrial by-product, slag has unique physical and chemical properties, which have a significant impact on its application.

In terms of physical properties, slag is a granulated foam that is light and brittle. This brittleness makes it easily broken when subjected to external forces, making it easier to grind. Its porous structure also gives it excellent water absorption, a property that is crucial in certain applications, such as sound-absorbing tiles or thermal insulation. The particle size distribution of slag also follows certain patterns, and slag of different particle sizes can have different effects when used. For example, finer slag powder can better fill and reinforce concrete.

Chemically, slag is primarily composed of compounds such as silicates and aluminates, and is rich in components such as CaO, SiO₂, and Al₂O₃. These chemical components give slag its potential chemical activity. When in contact with water or alkaline substances, the active components in slag undergo hydration reactions, forming a cementitious substance. This property enables slag to be used as an active admixture in cement and concrete production, replacing part of the cement and improving the strength and durability of concrete. The chemical composition of slag also varies depending on the ironmaking raw materials and processes, resulting in differences in the activity of slag from different sources.

The potential activity of slag is one of its most important physicochemical properties. This activity originates from the vitreous structure formed during the rapid cooling process. This structure, which contains numerous broken bonds and vacancies, possesses a high energy state. When slag comes into contact with water or an alkaline solution, the vitreous structure on its surface rapidly dissolves, releasing active components that react with water to form cementitious substances such as calcium silicate hydrate. These hydration products can fill pores in concrete, improving its density and strength.

The physical and chemical properties of slag determine its potential applications in multiple fields. In the construction industry, its brittleness and porous structure make it an excellent lightweight aggregate and thermal insulation material. In the environmental protection field, its adsorption properties can be used to treat wastewater and exhaust gas. These properties make slag an indispensable resource in industrial production.

1.3 Importance of slag in industry

Slag occupies a pivotal position in industry, and its importance is reflected in many fields.

In cement production, slag is a high-quality active admixture. When slag is added to cement clinker at a certain ratio and ground into cement, its potential activity can be activated during the cement hydration process, generating gelling substances and increasing cement strength. The addition of slag can also improve certain cement properties, such as reducing the heat of hydration and increasing its resistance to sulfate attack. This is of great significance for large-scale concrete projects and concrete structures exposed to harsh environments.

In the concrete industry, the role of slag is equally significant. Grinding slag into a fine powder and adding it to concrete as an admixture can significantly improve concrete’s performance. Slag powder has a strong filling effect, filling tiny pores in concrete and increasing its density, thereby enhancing its strength and durability. Slag powder also improves concrete’s workability, making mixing and pouring smoother while reducing bleeding and segregation. The addition of slag also reduces concrete costs and cement usage, resulting in excellent economic benefits.

In the building materials industry, slag can be used to produce a variety of building materials. For example, its lightweight and porous properties can be used to produce foamed silicate building products and slag sound-absorbing bricks. These products offer excellent thermal insulation, sound absorption, and noise reduction properties, and are widely used in building walls, roofs, and interior decoration. Slag can also be used as a raw material to produce slag wool, which is used in building insulation and fireproofing. The application of slag in the building materials industry not only increases its added value but also provides the construction industry with a wider range of high-performance green building materials.

The importance of slag in industry is also reflected in its contribution to environmental protection. As an industrial waste, its effective utilization reduces land resource occupation and environmental pollution caused by waste storage. Converting slag into useful products achieves resource recycling and aligns with the concept of sustainable development. With continuous technological advancements, the application areas of slag in industry will continue to expand, and its importance will become even more prominent.

2. Vertical mill introduction

2.1 Development History of Vertical Mill

The development of vertical grinding mills can be described as a long and arduous journey, with their birth and development always closely linked to industrial progress. As early as the early 20th century, with the continuous expansion of industrial production, the demand for grinding equipment increased, and people began to explore more efficient grinding methods. Vertical grinding mills came into being in this context.

Initially, vertical mills had a relatively simple structure and were primarily used in applications requiring less demanding grinding fineness, such as primary crushing. While their operating principles were initially established, the technology was still immature, and both grinding efficiency and stability needed to be improved. With the continuous advancement of technology, particularly the application of hydraulics, vertical mills experienced significant breakthroughs. The advent of hydraulic loading technology in the 1970s significantly increased the capacity of individual vertical mills and significantly improved their grinding efficiency. This application not only enabled vertical mills to gain prominence in industries such as cement production but also laid a solid foundation for their subsequent development.

Entering the 1980s, vertical mill technology was further optimized and improved. During this period, relevant research institutions in my country proposed vigorously promoting vertical mills in the cement industry, and vertical mills began to be widely used in various industries, including cement, electricity, metallurgy, and chemicals. With the emergence and development of precalciner kilns and suspension preheater kilns, the application of vertical mill technology in the cement production industry has become increasingly widespread.

By the late 1990s and early 2000s, vertical mill technology had made significant progress again, with the gradual promotion and application of vertical mills for final cement grinding and high-fine slag grinding. Vertical mills were increasingly used in cement plants, becoming an indispensable key piece of equipment in cement production. Simultaneously, the introduction of new grinding equipment such as drum roller mills and roller presses also promoted the development and application of bed grinding equipment in the cement production industry.

With the rapid development of society and the economy, resource and energy issues have become increasingly prominent, and energy conservation and environmental protection have become important directions for industrial development. Vertical mill technology is also continuously developing in the direction of energy conservation and emission reduction. Through optimizing structures and improving processes, efforts are being made to reduce energy consumption and emissions to meet the requirements of sustainable development. Today, vertical mills have become an ideal large-scale grinding equipment, playing an important role in various industries, and their future development potential remains enormous.

2.2 Working principle of vertical mill

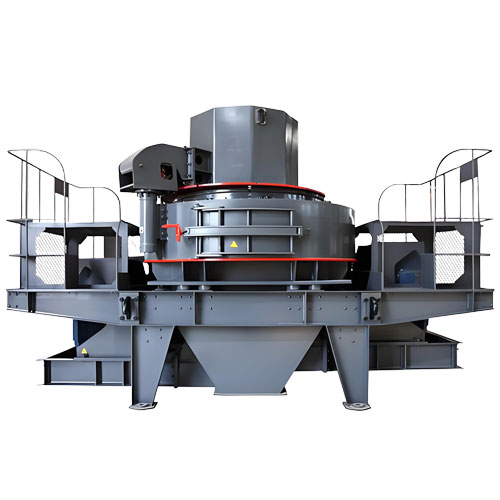

The working principle of a vertical mill is the core of its efficient grinding process, which primarily achieves grinding through the relative motion of the grinding roller and grinding disc. The vertical mill primarily consists of a grinding roller assembly, grinding disc assembly, hydraulic station, transmission arm assembly, powder classifier, main reducer, electric motor, machine body, main reducer lubrication station, hydraulic station, and PLC control cabinet.

During operation, the main motor drives the grinding disc through a speed reducer. The grinding disc is placed horizontally at the bottom of the vertical mill and driven by a rotary power source. When material falls from the discharge port onto the center of the grinding disc, centrifugal force causes the material to move evenly from the center to the edge of the grinding disc. As it passes through the grinding roller area on the grinding disc, it is crushed by the grinding rollers. Larger materials are directly crushed, while finer particles are squeezed to form a material bed for inter-particle comminution.

The grinding roller is a key component of a vertical mill. It extends from the side of the mill, above the grinding disc, and is fixed at an angle downward. Driven by a hydraulic system, the roller crushes the material that falls onto the grinding disc. The roller’s loading pressure can be adjusted hydraulically to suit the grinding requirements of different materials. As the roller and grinding disc move relative to each other, the material is squeezed and sheared in the gap between them, crushing it into finer particles.

The crushed material continues to move outward as the grinding discs move. During this process, hot air enters the mill through the air inlet, making full contact with the material. This hot air not only dries the material but also lifts it up. A powder classifier, located above the mill, separates the material according to particle size. Fine powder that meets the requirements is collected in the dust collector, while coarse powder falls back onto the grinding discs due to gravity and centrifugal force, where it continues to be ground until the desired particle size is achieved.

This operating principle of a vertical mill offers numerous advantages. It integrates crushing, drying, grinding, and graded conveying, resulting in high production efficiency and the ability to grind bulk, granular, and powdered materials into the desired powdered product. Furthermore, because the material is crushed between particles on the material bed, direct wear between metal components is reduced, lowering equipment maintenance costs. Furthermore, the grinding process is gentle, effectively preventing material overheating and over-grinding, ensuring the quality of the ground product.

Related Products

Inquiry

Please leave us your requirements, we will contact you soon.